Jun . 20, 2024 05:41 Back to list

Welded wire fabric concrete (WWFC)

Welded Wire Fabric (WWF) in Concrete Revolutionizing Construction

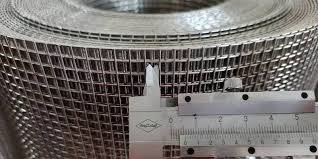

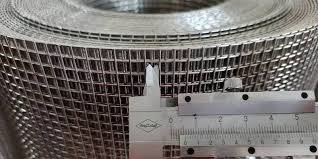

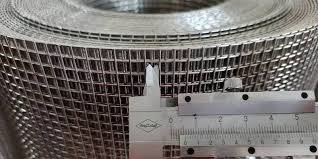

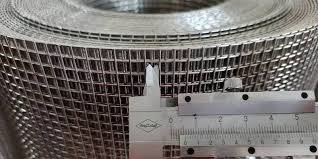

Welded wire fabric, often referred to as rebar mesh, is a steel reinforcement material that has been extensively used in the construction industry for decades. However, its application has evolved significantly with the advent of welded wire fabric concrete (WWFC), which offers numerous advantages over traditional reinforced concrete.

WWFC is created by weaving steel wires together and then welding them at designated intervals. This process results in a strong and durable grid that can be easily integrated into fresh concrete. The resulting composite material combines the strength of steel with the workability of concrete, leading to improved structural performance and reduced construction time.

One of the key benefits of WWFC is its ability to improve the durability of concrete structures. By distributing stress more evenly across the structure, WWFC reduces the risk of cracks and other forms of deterioration. This is particularly important in environments where concrete is exposed to heavy loads, such as highways, bridges, and parking garages.

In addition to improved durability, WWFC also offers significant cost savings. Because it allows for thinner concrete slabs and fewer steel bars, WWFC can reduce the amount of material required for a given project Because it allows for thinner concrete slabs and fewer steel bars, WWFC can reduce the amount of material required for a given project Because it allows for thinner concrete slabs and fewer steel bars, WWFC can reduce the amount of material required for a given project Because it allows for thinner concrete slabs and fewer steel bars, WWFC can reduce the amount of material required for a given project

Because it allows for thinner concrete slabs and fewer steel bars, WWFC can reduce the amount of material required for a given project Because it allows for thinner concrete slabs and fewer steel bars, WWFC can reduce the amount of material required for a given project welded wire fabric concrete. This not only lowers construction costs but also leads to less environmental impact, as there is less need for raw materials such as sand, gravel, and cement.

Furthermore, WWFC can help to speed up construction timelines. Because it is easier to handle and install than traditional rebar, WWFC can reduce the amount of time required for formwork, placement, and finishing. This can be especially beneficial in situations where tight deadlines are a concern.

Overall, the use of welded wire fabric concrete represents a major advancement in the construction industry. Its combination of strength, durability, cost savings, and speed makes it an attractive option for a wide range of projects. As awareness of its benefits continues to grow, it is likely that we will see even more widespread adoption of WWFC in the years ahead.

welded wire fabric concrete. This not only lowers construction costs but also leads to less environmental impact, as there is less need for raw materials such as sand, gravel, and cement.

Furthermore, WWFC can help to speed up construction timelines. Because it is easier to handle and install than traditional rebar, WWFC can reduce the amount of time required for formwork, placement, and finishing. This can be especially beneficial in situations where tight deadlines are a concern.

Overall, the use of welded wire fabric concrete represents a major advancement in the construction industry. Its combination of strength, durability, cost savings, and speed makes it an attractive option for a wide range of projects. As awareness of its benefits continues to grow, it is likely that we will see even more widespread adoption of WWFC in the years ahead.

Because it allows for thinner concrete slabs and fewer steel bars, WWFC can reduce the amount of material required for a given project Because it allows for thinner concrete slabs and fewer steel bars, WWFC can reduce the amount of material required for a given project

Because it allows for thinner concrete slabs and fewer steel bars, WWFC can reduce the amount of material required for a given project Because it allows for thinner concrete slabs and fewer steel bars, WWFC can reduce the amount of material required for a given project welded wire fabric concrete. This not only lowers construction costs but also leads to less environmental impact, as there is less need for raw materials such as sand, gravel, and cement.

Furthermore, WWFC can help to speed up construction timelines. Because it is easier to handle and install than traditional rebar, WWFC can reduce the amount of time required for formwork, placement, and finishing. This can be especially beneficial in situations where tight deadlines are a concern.

Overall, the use of welded wire fabric concrete represents a major advancement in the construction industry. Its combination of strength, durability, cost savings, and speed makes it an attractive option for a wide range of projects. As awareness of its benefits continues to grow, it is likely that we will see even more widespread adoption of WWFC in the years ahead.

welded wire fabric concrete. This not only lowers construction costs but also leads to less environmental impact, as there is less need for raw materials such as sand, gravel, and cement.

Furthermore, WWFC can help to speed up construction timelines. Because it is easier to handle and install than traditional rebar, WWFC can reduce the amount of time required for formwork, placement, and finishing. This can be especially beneficial in situations where tight deadlines are a concern.

Overall, the use of welded wire fabric concrete represents a major advancement in the construction industry. Its combination of strength, durability, cost savings, and speed makes it an attractive option for a wide range of projects. As awareness of its benefits continues to grow, it is likely that we will see even more widespread adoption of WWFC in the years ahead. Latest news

-

Welded Wire Mesh for Industry Factory - Durable & Strong

NewsAug.16,2025

-

Glass Jar with Wooden Screw Lid - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable, Eco-Friendly Food Storage

NewsAug.15,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile Fencing

NewsAug.15,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable Security&Wire Mesh

NewsAug.15,2025

-

Chain Link Fence: Durable & Versatile Security Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.15,2025

-

Chain Link Fence-Durable&Versatile|Anping County Puersen

NewsAug.15,2025