Sep . 04, 2024 17:29 Back to list

welded wire fabric concrete suppliers

Welded Wire Fabric Concrete Suppliers A Key Resource in Construction

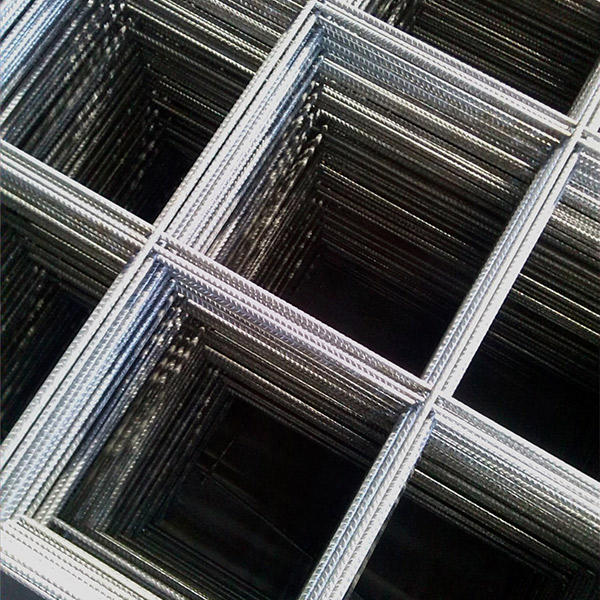

In the construction industry, the significance of high-quality materials cannot be overstated. Among these, welded wire fabric (WWF), often referred to as welded wire mesh, has become a staple in reinforcing concrete structures. For contractors, architects, and construction managers, sourcing welded wire fabric from reliable suppliers is crucial for ensuring structural integrity and durability.

Welded wire fabric consists of a grid of steel wires, welded together at intersections to form a strong, flexible mesh. It is widely used in various applications, including slabs, pavements, foundations, and retaining walls. The mesh improves the tensile strength of concrete, reducing cracking and enhancing overall performance. This combination of strength and flexibility makes welded wire fabric an ideal reinforcement solution in a range of construction contexts.

When selecting a welded wire fabric supplier, several factors should be considered. First and foremost is the supplier's reputation within the industry. Established suppliers with a history of delivering quality materials tend to maintain high standards of production and customer service. Reviews and testimonials from previous clients can provide insights into a supplier's reliability and product quality.

Additionally, it is essential to ensure that the supplier complies with industry standards and regulations. Credentials, such as certifications from organizations like ASTM International or the American Concrete Institute, indicate that the welded wire fabric meets high-quality specifications. Furthermore, suppliers should be able to provide documentation that demonstrates the strength and durability of their products.

welded wire fabric concrete suppliers

Another important consideration is the range of products offered by the supplier. The construction industry has diverse needs, and suppliers that provide a variety of welded wire mesh specifications can cater to different projects. This includes various wire diameters, spacing configurations, and mesh sizes that can be tailored to meet specific structural requirements. A supplier that can offer customized solutions may be better positioned to support unique project demands.

Moreover, timing and availability are critical in construction. Delays in material supply can hold up projects and increase costs significantly. Therefore, reliable suppliers that can guarantee timely delivery are invaluable. Many modern suppliers use technological advancements in logistics and inventory management to ensure they can meet project deadlines effectively.

Cost is another vital factor to consider when choosing a supplier. While sourcing the lowest price is tempting, it is crucial to balance cost with quality. The cheapest option may not always provide the best value if it compromises the structural integrity of the project. Comparing quotes from different suppliers can help in finding a balance between quality and budget.

Finally, excellent customer service should never be overlooked. Suppliers who are willing to provide technical support and advice can be invaluable, especially when navigating complex project specifications or troubleshooting issues. A strong partnership with a supplier can lead to smoother project execution and better outcomes.

In conclusion, selecting the right welded wire fabric concrete supplier is essential for the success of any construction project. By considering reputation, compliance with industry standards, product range, delivery reliability, and customer support, construction professionals can ensure they choose a supplier that meets their specific needs. The right choice will not only enhance the quality of the project but also contribute to its longevity and sustainability.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025