Aug . 10, 2024 20:30 Back to list

Understanding the Various Sizes of Welded Wire Mesh for Concrete Applications and Their Benefits

Understanding Welded Wire Mesh Sizes for Concrete

Welded wire mesh is a critical component in modern concrete construction, known for its ability to enhance the structural integrity of concrete elements. When it comes to selecting the appropriate welded wire mesh sizes for concrete applications, several factors come into play, including the type of project, load requirements, and the specific characteristics of the concrete mix.

What is Welded Wire Mesh?

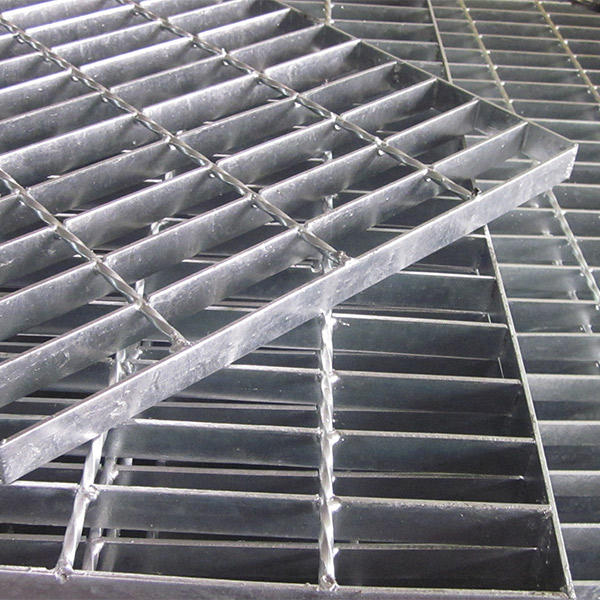

Welded wire mesh consists of a series of interconnected steel wires that are welded together at their intersections to form a grid-like structure. This mesh is primarily used to reinforce concrete slabs and walls, providing tensile strength and controlling cracking due to shrinkage and temperature changes. The mesh is available in various sizes, wire diameters, and spacing configurations, making it adaptable to different construction needs.

Common Sizes and Specifications

Welded wire mesh is categorized by its size and the gauge of the wire. Standard sizes often include measurements such as 4x4 inches or 6x6 inches, with wire diameters ranging from 10 to 16 gauges. The choice of size and wire gauge will depend on various factors, including the anticipated load and the thickness of the concrete being poured.

For instance, for residential concrete slabs that support light loads, a 6x6 mesh with 10-gauge wire may suffice. Conversely, for commercial applications or areas subjected to higher loads, a 4x4 mesh with 8-gauge wire might be more appropriate, providing extra strength and durability.

Factors Influencing Mesh Selection

welded wire mesh sizes for concrete

1. Load Requirements The first step in choosing the correct welded wire mesh size involves assessing the load that will be applied to the concrete. For higher loads, a denser mesh with thicker wires is recommended to ensure proper reinforcement.

2. Concrete Thickness The thickness of the concrete slab plays a significant role in mesh selection. Thicker slabs may require different mesh configurations compared to thinner ones to accommodate the additional stress.

3. Environmental Conditions In areas prone to harsh weather conditions or variable temperatures, using a welded wire mesh with higher resistance to corrosion, such as epoxy-coated wire, can prolong the life of the concrete structure.

4. Placement Techniques The method of concrete placement can also influence the size and type of wire mesh used. For example, in projects where the concrete might be subjected to vibration during placement, a more robust mesh structure may be needed to maintain stability and strength.

Installation Considerations

Proper installation of welded wire mesh is crucial to its effectiveness. The mesh should be placed at the correct depth within the concrete slab to ensure that it contributes effectively to the tensile strength. Typically, the mesh should sit at the midpoint of the slab's thickness. Moreover, ensuring that the mesh remains in place during concrete pouring is essential, as any displacement can compromise its intended structural benefits.

Conclusion

Selecting the right size of welded wire mesh for concrete is an essential aspect of reinforced concrete design and construction. By understanding the various sizes, wire gauges, and the factors affecting mesh selection, contractors can optimize the strength and durability of their concrete structures. This not only leads to safer and longer-lasting buildings but also enhances the overall integrity of construction projects across various sectors.

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025

-

Welded Wire Mesh for Industry | Factory Direct Supplies

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Eco-Friendly, Heat-Resistant, Durable

NewsAug.17,2025