Nov . 21, 2024 13:47 Back to list

twisted bars for grating welding

Twisted Bars for Grating Welding A Comprehensive Overview

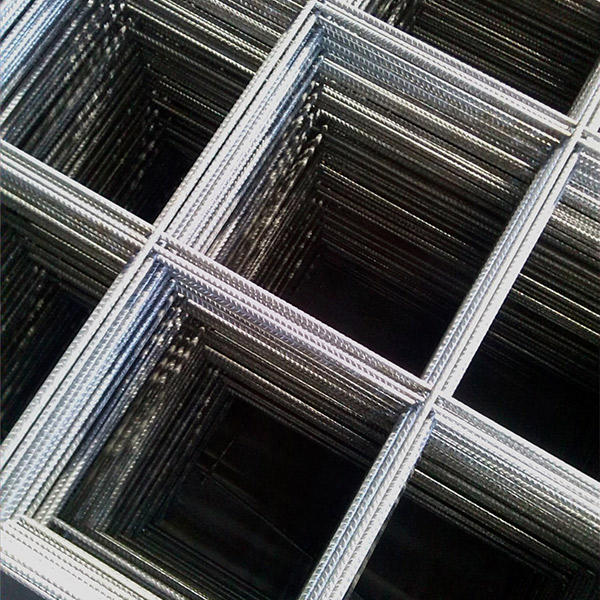

Grating is a widely utilized structural component in various industries, providing a robust solution for flooring, walkways, and industrial platforms. Among the many materials and methods used in the manufacturing of grating, twisted bars have emerged as a significant innovation. The use of twisted bars for grating welding has been gaining traction due to their mechanical strength, durability, and versatility in application.

Understanding Twisted Bars

Twisted bars, also known as twisted rebars, are reinforcement bars that undergo a twisting process during their manufacturing. This unique twist imparts certain mechanical properties that enhance their performance in various applications. The twisting creates a surface area that improves bonding with concrete, leading to superior strength and stability in structures. The inherent characteristics of twisted bars, such as improved tensile strength and resistance to bending, make them an ideal choice for grating applications.

Benefits of Using Twisted Bars in Grating Welding

1. Enhanced Mechanical Properties Twisted bars offer superior mechanical properties compared to traditional straight reinforcement bars. The torsional strength provided by the twisting process allows for higher load-bearing capacities, making them suitable for heavy-duty applications.

2. Improved Bonding The unique surface texture of twisted bars promotes better adhesion to the surrounding materials, particularly in welding environments. This characteristic reduces the risk of delamination and enhances the longevity of welded joints.

3. Corrosion Resistance Many twisted bars are treated with anti-corrosive coatings or are made from stainless steel. This resistance to environmental factors extends the service life of grating structures, making them ideal for outdoor or industrial environments where exposure to moisture and chemicals is common.

twisted bars for grating welding

4. Lightweight Design Despite their strength, twisted bars can be designed to be relatively lightweight. This attribute simplifies handling and installation processes, making them a preferred choice for many construction projects.

5. Versatility Twisted bars can be adapted for various designs and patterns in grating. They can be cut and shaped easily during the welding process, allowing for custom configurations that meet specific structural requirements.

Applications in Grating Welding

The application of twisted bars in grating welding spans multiple industries, including construction, manufacturing, and even aerospace. In construction, twisted bars are often used in building walkways, staircases, and maintenance platforms where safety and strength are paramount. In manufacturing settings, these bars contribute to the creation of grating that supports heavy machinery and equipment, ensuring stability and safety in high-traffic areas.

Additionally, the aesthetic qualities of twisted bars can enhance the visual appeal of grating. They can be incorporated into designs that not only provide functional benefits but also elevate the architectural aspects of a structure. This combination of strength, utility, and aesthetics makes twisted bars a desirable option for modern construction projects.

Conclusion

In conclusion, twisted bars for grating welding represent a significant advancement in the design and construction of grating systems. Their superior mechanical properties, enhanced bonding capabilities, corrosion resistance, and versatility make them an ideal choice for a variety of applications. As industries continue to evolve and demand stronger, more durable materials, twisted bars are likely to play an increasingly pivotal role in the future of structural engineering and construction. Embracing this innovative approach not only improves the performance and safety of grating systems but also contributes to the sustainability and longevity of modern infrastructure. Whether for industrial applications or aesthetic architectural designs, twisted bars are positioned to meet the challenges of contemporary construction demands effectively.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025