Dec . 09, 2024 18:49 Back to list

Twisted Annealed Wire Production by Leading Manufacturers in the Industry

The Evolution of Twisted Annealed Wire Manufacturing

In the realm of wire manufacturing, twisted annealed wire stands out as an essential material used in various applications, from electrical connectors to jewelry design

. As a manufacturer of twisted annealed wire, it is crucial to understand the properties, manufacturing processes, and market demand that drive this industry.Twisted annealed wire is created by taking several strands of wire and twisting them together, followed by an annealing process that enhances the metal's ductility and electrical conductivity. Typically made from materials such as copper, aluminum, or steel, these wires are often coated with insulating materials to suit specific applications. The twisting process serves not only to provide strength but also to facilitate flexibility, allowing for easier handling and installation.

One of the key advantages of twisted annealed wire is its durability. The annealing process reduces brittleness, making the wire less prone to breaking under stress. This property is particularly important in applications where the wire will be subjected to repeated movement or mechanical loads. Additionally, the twisted design helps distribute stress evenly across the wire, preventing localized weakness that could lead to failure.

Manufacturing twisted annealed wire involves several critical steps. First, raw materials are sourced and processed into wire strands. This often begins with drawing copper or aluminum to achieve the desired gauge. Once the strands are prepared, they are twisted together using advanced machinery that ensures precision and uniformity. The twisting process not only strengthens the wire but also enhances its electrical properties, making it ideal for use in electrical applications.

twisted annealed wire manufacturer

Following this, the wire undergoes the annealing process, where it is heated to a specific temperature and then cooled. This controlled heating alters the microstructure of the metal, allowing it to become more malleable. The cooling process is equally important, as it helps to lock in the properties achieved during heating. The result is a high-quality twisted annealed wire that is both strong and flexible.

The applications of twisted annealed wire are vast and diverse. In the electrical industry, it is commonly used for wiring in homes and industries, as it offers excellent conductivity and strength. Moreover, its flexibility enables easy routing through tight spaces. In jewelry making, twisted annealed wire adds an aesthetic quality, allowing artisans to create intricate designs while maintaining the structural integrity of their pieces.

The demand for twisted annealed wire has seen remarkable growth in recent years, driven by advancements in technology and an increase in construction and manufacturing activities worldwide. As industries evolve and the need for innovative solutions increases, wire manufacturers are tasked with producing high-quality, versatile products.

Furthermore, sustainability is becoming a focal point for many manufacturers. With increasing awareness of environmental issues, companies are exploring ways to reduce waste and energy consumption during the manufacturing process. Employing recycling methods for raw materials and investing in eco-friendly technologies can enhance a manufacturer’s reputation and operational efficiency.

In conclusion, twisted annealed wire plays a pivotal role in various industries, offering a unique blend of strength, flexibility, and conductivity. As a leading manufacturer in this domain, embracing advancements in technology and sustainable practices will not only improve product quality but also cater to the evolving needs of the market. The future of twisted annealed wire manufacturing is bright, driven by innovation and the unwavering demand for high-performance materials.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

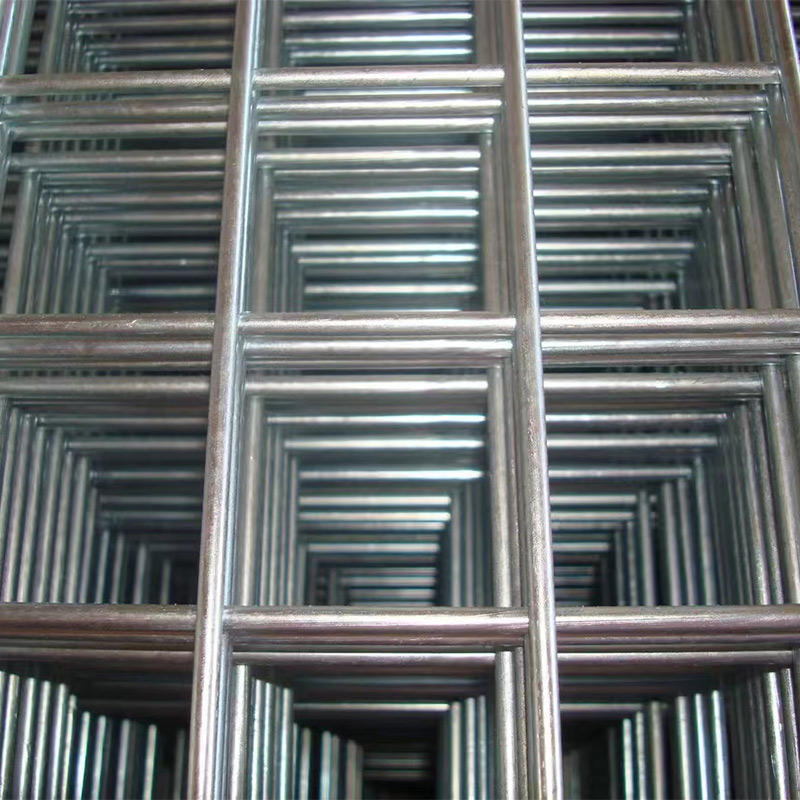

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025