Nov . 20, 2024 17:19 Back to list

twisted annealed wire

Twisted Annealed Wire An Overview and Applications

Twisted annealed wire is an important material in various industrial and manufacturing processes, known for its unique properties and versatility. The process of twisting and annealing wire enhances its mechanical strength, flexibility, and resistance to fatigue. This article delves into the characteristics, manufacturing process, and applications of twisted annealed wire, showcasing its significance in various sectors.

Characteristics of Twisted Annealed Wire

Twisted annealed wire is typically made from metals such as copper, aluminum, or steel. The twisting process involves twisting multiple strands of metal together, which increases the wire's tensile strength and reduces the likelihood of breakage. Following the twisting process, the wire is subjected to annealing. This heat treatment process softens the metal, relieving internal stresses and making it more ductile. As a result, twisted annealed wire is more pliable and easier to work with compared to non-annealed counterparts.

One of the most notable characteristics of twisted annealed wire is its exceptional flexibility. This flexibility allows for easy handling and installation in various applications, making it a preferred choice for electrical wiring, construction, and more. Additionally, the twisted structure provides greater resistance against bending and deformation, which is crucial in applications where the wire is subjected to dynamic forces.

Manufacturing Process

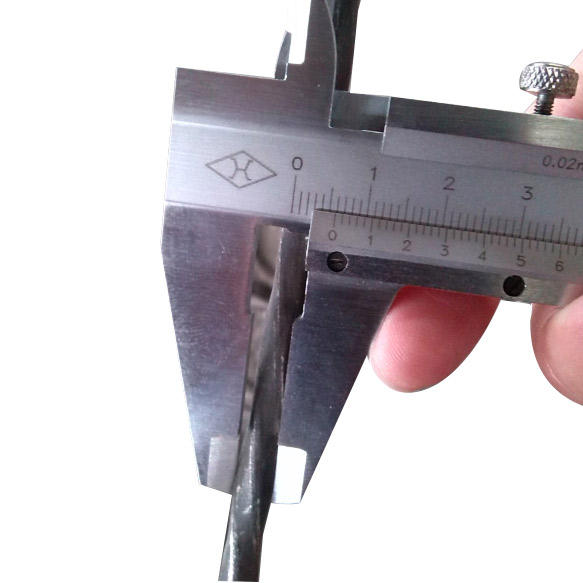

The manufacturing of twisted annealed wire involves several key steps. Initially, the raw material is drawn to the desired diameter, determining the wire’s thickness. Once the desired gauge is achieved, the wire strands are twisted together using specialized machinery. This twisting can vary in the number of strands and the twist rate, depending on the intended application.

After twisting, the wire undergoes the annealing process. This is typically done in a controlled environment, where the wire is heated to a specific temperature to achieve the desired softness. The annealing process can be adjusted according to the material type and desired mechanical properties. Once cooled, the twisted annealed wire is inspected for quality, ensuring that it meets the necessary standards before it is packaged and shipped.

twisted annealed wire

Applications of Twisted Annealed Wire

The versatility of twisted annealed wire makes it suitable for a wide range of applications across different industries. One of the most prominent uses is in electrical wiring. The flexibility and conductivity of twisted copper wire make it ideal for various electrical applications, including power transmission and telecommunications. The twist not only enhances its mechanical strength but also reduces electromagnetic interference, improving signal quality.

In the construction industry, twisted annealed wire is often used for reinforcing concrete structures. The combination of strength and flexibility allows it to be woven into reinforced concrete, providing stability and durability to buildings and infrastructure.

Moreover, twisted annealed wire finds applications in the automotive industry. It is used in wiring harnesses, which are critical for the distribution of electrical signals within vehicles. For similar reasons, it is also used in manufacturing various mechanical components where flexibility and resilience are necessary.

In the realm of art and design, twisted annealed wire is favored by artists and sculptors for creating intricate designs and structures. Its ease of manipulation allows for creativity without compromising strength.

Conclusion

Twisted annealed wire is a remarkable material that combines strength, flexibility, and versatility. Its unique properties make it essential in various fields, from electrical engineering to construction and artistic endeavors. As technology continues to evolve, the demand and applications for this versatile wire are likely to expand, underscoring its importance in modern manufacturing and design practices. Understanding its characteristics and applications is crucial for engineers, manufacturers, and designers keen on leveraging the benefits of twisted annealed wire in their projects.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025