Aug . 13, 2024 03:12 Back to list

Top Manufacturers of Premium Quality Black Annealed Wire for Diverse Industrial Applications

High-Quality Black Annealed Wire Factories A Closer Look

The wire manufacturing industry plays a vital role in various sectors, from construction and agriculture to automotive and electrical applications. Among the numerous types of wire products available, black annealed wire has gained significant attention for its unique properties and versatile uses. This article delves into the characteristics of high-quality black annealed wire and the factors that contribute to the success of factories specializing in its production.

Understanding Black Annealed Wire

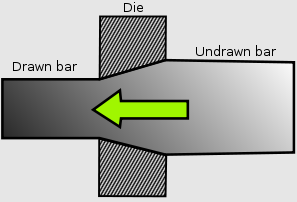

Black annealed wire is a type of low-carbon steel wire that undergoes a specialized annealing process. This process involves heating the wire to a certain temperature and then cooling it, resulting in improved ductility and malleability. The wire is typically coated with a layer of oxides, giving it a dark finish that is both appealing and functional. Its strength, flexibility, and resistance to corrosion make it an ideal choice for various applications, such as fencing, binding, and reinforcing structures.

The Importance of Quality

Quality is paramount when it comes to black annealed wire. High-quality products are essential for ensuring durability and performance in end applications. Factories that specialize in producing black annealed wire prioritize quality control at every step of their manufacturing process. This includes sourcing premium raw materials, employing advanced manufacturing techniques, and conducting rigorous testing on finished products.

1. Raw Materials The foundation of high-quality black annealed wire begins with the selection of raw materials. Factories often use low-carbon steel wire rods, which provide the necessary properties for effective annealing and subsequent use. By partnering with reliable suppliers, manufacturers can ensure consistency and quality in their final products.

high quality black annealed wire factories

2. Manufacturing Techniques The annealing process itself is critical in determining the wire's properties. Factories that utilize modern technology and equipment are better equipped to control temperatures and processes, resulting in a superior product. Techniques such as controlled atmosphere annealing can further enhance properties such as ductility and tensile strength.

3. Testing and Standards Leading black annealed wire factories implement stringent quality assurance measures to ensure their products meet industry standards. This includes physical and chemical testing to assess tensile strength, elongation, and resistance to corrosion. By adhering to international standards such as ASTM and ISO, factories can provide products that meet the highest level of expectations from consumers.

Sustainability and Environmental Considerations

In recent years, sustainability has become a pressing concern in manufacturing. High-quality black annealed wire factories are increasingly adopting eco-friendly practices to minimize their environmental impact. This includes optimizing manufacturing processes to reduce energy consumption and waste, as well as implementing recycling programs for scrap material.

Moreover, companies are exploring the use of sustainable materials and eco-friendly coatings that reduce the environmental footprint of their products. By prioritizing sustainability, these factories not only contribute to environmental preservation but also appeal to a growing market that values ethical production practices.

Conclusion

High-quality black annealed wire is essential in a plethora of industries, and the factories that produce it play a critical role in ensuring its reliability and performance. By focusing on quality raw materials, advanced manufacturing techniques, and rigorous testing processes, these factories can create products that meet the diverse needs of their customers. Additionally, as sustainability becomes an increasingly vital aspect of manufacturing, those that embrace eco-friendly practices will likely stand out in a competitive market. Ultimately, the future of black annealed wire and its producers hinges on a commitment to quality, innovation, and environmental responsibility.

-

Glass Jar with Wooden Screw Lid-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Thermal Resistance&Eco-Friendly

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|High Borosilicate Glass&Eco-Friendly Design

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Thermal Resistance Eco-Friendly Airtight Seal

NewsAug.17,2025

-

Glass Jar with Wooden Screw Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.17,2025

-

Diamond Steel Grating Factory: Leading Manufacturer & Supplier

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Premium Eco-Friendly Storage Solution|Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsAug.16,2025