Aug . 13, 2024 09:50 Back to list

Top Manufacturers of Durable and Affordable Black Binding Wire in the Market Today

The Significance of Black Binding Wire Manufacturers in Today's Market

In the construction and manufacturing industries, the common yet essential tool known as binding wire plays a crucial role. Among various types, black binding wire is particularly prominent. Its high tensile strength, flexibility, and corrosion resistance make it an optimal choice for reinforcing materials. The manufacturers of black binding wire have been pivotal in meeting the diverse needs of the marketplace. This article explores the importance of these manufacturers and the factors driving their relevance in today's economy.

Understanding Black Binding Wire

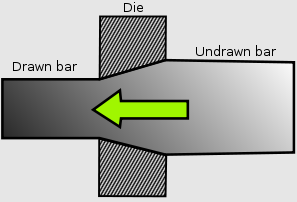

Black binding wire is typically made of mild steel and is used extensively in construction and various industrial applications. Its primary purpose is to hold materials together, particularly when reinforcing concrete structures, creating cages for rods, or bundling items during transport. The surface of black wire is usually not coated, giving it a dark appearance due to the manufacturing process, which includes drawing the wire with a specific finish that prevents rusting.

Role of Manufacturers

The significance of black binding wire manufacturers cannot be overstated. They play a crucial role in the production line, producing wires that meet stringent quality standards. These manufacturers employ advanced technology and skilled labor to ensure that the wire produced is durable and reliable. Their ability to scale production based on market demand is essential, as construction projects often have fluctuating requirements.

Furthermore, these manufacturers are responsible for innovating new processes and materials that enhance the quality of binding wire. For example, advancements in coating technologies allow for protective layers that extend the lifespan of the wire, making it suitable for varying environmental conditions. As sustainability becomes a greater concern, manufacturers are also exploring eco-friendly alternatives and production methods that reduce waste and energy consumption.

Market Demand and Trends

black binding wire manufacturers

In recent years, the demand for black binding wire has surged due to the growing construction and infrastructure developments worldwide. Developing economies are particularly active, with governments investing significantly in infrastructure projects. This has resulted in an increased need for reliable binding solutions.

Moreover, the rise of prefabricated constructions has led to new applications for black binding wire. As manufacturers adapt to these trends, they are also diversifying their product lines to include various wire gauges and packaging options that cater to specific industry needs. The shift toward smart construction technologies has further driven demand, with black binding wire being integral to the assembly and transportation of modular construction elements.

Challenges Faced by Manufacturers

Despite the growing market, black binding wire manufacturers face challenges. The volatility of raw material prices, particularly steel, can impact production costs significantly. Additionally, international trade policies and tariffs can alter market dynamics, forcing manufacturers to remain agile in their operations.

Moreover, with increasing global awareness of sustainability, manufacturers are under pressure to develop greener production practices and products. This includes reducing carbon footprints and utilizing recyclable materials, which adds another layer of complexity to manufacturing processes.

Conclusion

Black binding wire manufacturers play an indispensable role in the construction and manufacturing sectors. Their ability to produce quality products that meet market demands ensures the continuation of infrastructure development and innovation. As the industry evolves with technological advancements and sustainability trends, these manufacturers are likely to adapt, paving the way for further growth and efficiency in the market. The future looks bright for black binding wire manufacturers as they continue to rise to the challenges of a dynamic economy while providing essential materials for various applications.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025