Aug . 12, 2024 16:22 Back to list

Supplier of Reinforcing Wire Mesh A193 for Construction and Industrial Applications Worldwide

The Role of Reinforcing Wire Mesh A193 in Construction and Its Suppliers

Reinforcing wire mesh, specifically grade A193, plays a crucial role in modern construction, providing strength and stability to a wide range of concrete structures. This article explores the significance of A193 wire mesh, its applications, and the importance of reliable suppliers in ensuring quality and compliance with construction standards.

Understanding A193 Reinforcing Wire Mesh

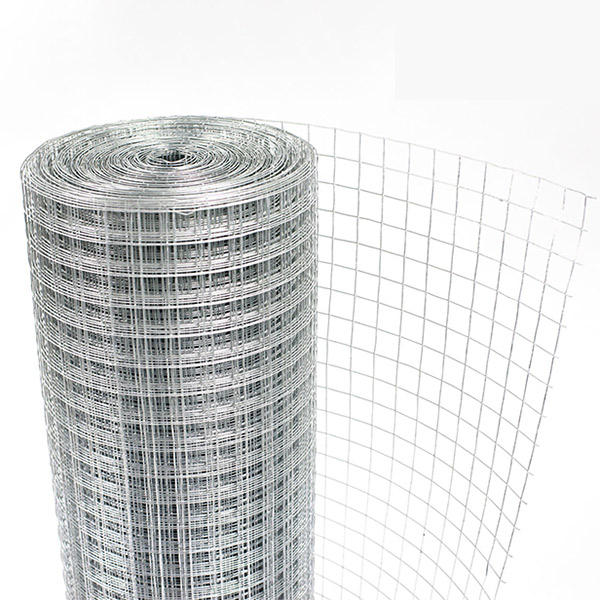

Wire mesh is an essential component in the construction industry, primarily used to reinforce concrete. The grading system, which includes A193, specifies the wire mesh’s mechanical properties and suitability for various applications. A193 wire mesh is known for its robust tensile strength and structural integrity, making it ideal for use in commercial, industrial, and residential projects. This type of wire mesh is typically made from high-quality steel, which is cold drawn into wires and welded together to form a grid pattern.

Applications of Reinforcing Wire Mesh A193

The applications for A193 reinforcing wire mesh are varied and extensive. It is commonly used in

1. Foundation and Slab Construction A193 wire mesh is often implemented in the foundation and slab of buildings, providing reinforcement that helps distribute loads evenly. This minimizes the risk of cracking and structural failure, particularly in areas subjected to heavy loads or environmental factors.

2. Pavements and Driveways In constructing pavements, sidewalks, and driveways, A193 wire mesh is utilized to enhance durability and longevity. The mesh helps to prevent cracking and shifting caused by heavy traffic and changing weather conditions.

3. Walls and Retaining Structures Reinforced concrete walls, including retaining walls, benefit from the added strength of A193 wire mesh. Its grid structure enhances the wall's ability to support lateral loads, ensuring stability.

4. Precast Concrete Products A193 wire mesh is also integral in the manufacturing of precast concrete elements, such as panels, beams, and blocks, where consistent strength is required across the production.

reinforcing wire mesh a193 supplier

Importance of Quality Suppliers

The effectiveness of A193 wire mesh in construction largely depends on the quality of the material used. Thus, finding a reputable supplier is essential for any construction project. A reliable supplier ensures that the wire mesh meets industry standards and specifications. Here are several factors to consider when choosing a supplier

1. Compliance with Standards The supplier should provide wire mesh that complies with national and international standards. Documentation and certification verify that the products meet required specifications, which is vital for safety and performance.

2. Material Quality High-quality steel should be used in producing A193 wire mesh to ensure strength and longevity. Suppliers should be able to provide details about the material properties, including tensile strength and corrosion resistance.

3. Range of Products A good supplier will offer a wide variety of wire mesh options to meet diverse project requirements, including different sizes, coatings, and configurations.

4. Customer Support Reliable customer support is essential. Suppliers should be knowledgeable about their products and able to assist with technical questions, helping customers make informed decisions.

5. Timely Delivery Construction projects are often time-sensitive. A reputable supplier can ensure timely delivery of products, avoiding delays in project schedules.

Conclusion

Reinforcing wire mesh A193 is an integral component in contemporary construction, enhancing the strength and durability of various structures. By choosing a trustworthy supplier, contractors and builders can ensure they are getting high-quality materials that meet necessary standards. As the construction industry continues to evolve, the demand for reliable reinforcing solutions like A193 wire mesh will remain crucial for building safe and enduring infrastructure.

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025

-

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

NewsJun.10,2025

-

Galvanized Wire Brick Force Mesh - Corrosion Resistant

NewsJun.09,2025