Aug . 17, 2024 18:01 Back to list

Stud Bolt ASTM A193 B16 Manufacturing Process and Quality Standards Overview

Understanding ASTM A193 B16 Stud Bolts Manufacturing and Applications

Stud bolts are integral components in various industrial applications, serving as critical fasteners that provide necessary support and structural integrity. Among the different types of stud bolts, ASTM A193 B16 stud bolts stand out due to their specific chemical composition, mechanical properties, and applications in high-pressure and high-temperature environments.

ASTM A193 Standard Overview

ASTM A193 is an international standard that covers alloy and stainless steel bolting materials for high-temperature or high-pressure service and other special purpose applications. The standard specifies the mechanical properties required for various grades of bolts, ensuring they can withstand extreme conditions. The B16 designation refers to a specific grade of stud bolts made from a high alloy steel, providing excellent strength and corrosion resistance.

Material Composition

Stud bolts labeled as ASTM A193 B16 are typically made from chromium-molybdenum alloy steel. The alloying elements, particularly chromium and molybdenum, enhance the mechanical properties, allowing these bolts to maintain their integrity in adverse conditions. This unique composition provides superior tensile strength and resistance to stress corrosion cracking, making them suitable for environments such as chemical processing plants, oil and gas applications, and power generation facilities.

Manufacturing Process

stud bolt astm a193 b16 factory

The manufacturing of ASTM A193 B16 stud bolts involves several steps to ensure quality and reliability. Initially, high-quality raw materials are sourced, followed by the forging or threading process, during which the material is shaped into the desired dimensions. Heat treatment is then performed to enhance the material's properties, including hardening and tempering processes that significantly increase tensile strength.

Quality control is a crucial aspect of the manufacturing process. Each batch of stud bolts undergoes rigorous testing, including tensile tests, yield strength tests, and chemical composition analysis, to ensure compliance with ASTM specifications. Non-destructive testing (NDT) methods are also employed to identify any internal flaws that could compromise the bolts' integrity in high-stress applications.

Applications

The unique characteristics of ASTM A193 B16 stud bolts make them ideal for various applications across different industries. In oil and gas, these bolts are extensively used in flanges, valves, and piping systems where they must withstand high pressures and corrosive environments. In the power generation sector, they are crucial for mounting heavy machinery, turbines, and heat exchangers, where reliability is paramount.

In the chemical industry, ASTM A193 B16 stud bolts play a pivotal role in constructing pressure vessels and reactors, ensuring secure connections that can handle volatile substances safely. Their ability to operate efficiently in high-temperature conditions is invaluable in such applications, where failure could lead to catastrophic consequences.

Conclusion

ASTM A193 B16 stud bolts are a testament to advanced engineering and manufacturing processes designed to meet the demanding requirements of modern industries. By understanding the material composition, manufacturing methods, and applications of these critical fasteners, manufacturers and engineers can make informed decisions when selecting the right components for their projects. As industries continue to evolve, the importance of high-quality fasteners like ASTM A193 B16 stud bolts will remain essential in maintaining safety, efficiency, and structural integrity. Companies seeking reliable and durable fastening solutions will continue to turn to these high-performance stud bolts, ensuring optimal performance in even the most challenging environments.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

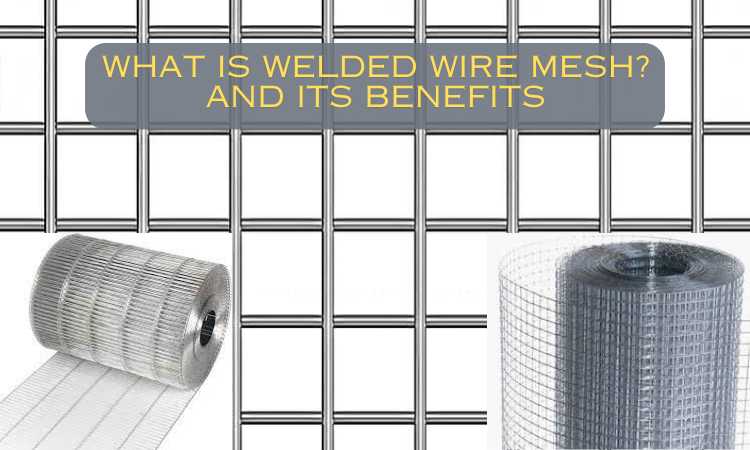

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025