Nov . 13, 2024 07:20 Back to list

steel wire mesh price factories

Understanding Steel Wire Mesh Price Factors

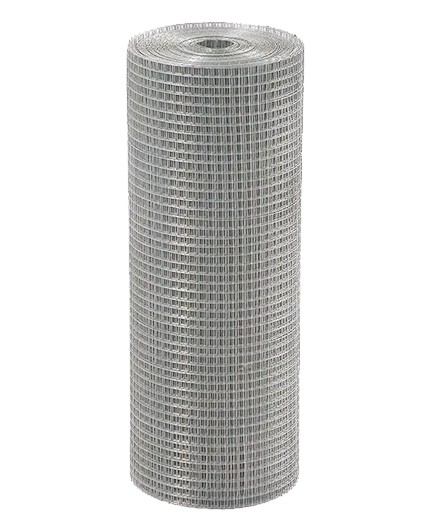

Steel wire mesh is an essential material widely used in construction, manufacturing, and various industrial applications. Its price can vary significantly based on a variety of factors. Here, we will explore the key elements that influence the pricing of steel wire mesh, helping buyers make informed purchasing decisions.

1. Material Quality The type of steel used plays a crucial role in determining the price of wire mesh. Higher-grade materials, such as stainless steel or galvanized steel, generally cost more due to their enhanced durability and resistance to corrosion. Conversely, low-carbon steel mesh tends to be more affordable but may not offer the same longevity.

2. Wire Diameter The thickness of the wire also affects the price. Thicker wires lead to stronger mesh but require more raw material, raising production costs. Buyers must balance the need for strength with their budget. For applications requiring high tensile strength, investing in a thicker mesh may be worthwhile.

3. Mesh Size and Configuration The size of the mesh openings and the overall dimensions of the wire mesh contribute to its price. Larger or custom-sized panels often involve additional processing and handling, which can increase costs. Additionally, specific configurations, such as welded or woven wire mesh, may have different pricing structures based on manufacturing complexity.

steel wire mesh price factories

4. Manufacturing Process The methods used to produce wire mesh can vary and impact pricing. For instance, welded wire mesh typically undergoes a more labor-intensive process compared to woven wire mesh, which can affect its price. Factories that employ advanced technology and automation may also have different pricing models due to efficiencies gained in production.

5. Quantity and Ordering Buying in bulk usually results in lower per-unit costs. Many manufacturers offer discounts for large orders, which can significantly reduce the overall expense. Therefore, planning ahead and estimating material needs can lead to substantial savings.

6. Market Demand and Supply Lastly, the fluctuating market demand for steel products can influence prices. During periods of high demand or supply chain disruptions, prices tend to rise. Conversely, during times of low demand, prices may decrease.

In conclusion, understanding the various factors influencing steel wire mesh prices can help buyers make strategic decisions. By considering material quality, wire diameter, mesh size, manufacturing processes, order quantity, and market dynamics, companies can source the right steel wire mesh to meet their needs at a competitive price.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025