Nov . 22, 2024 09:39 Back to list

steel welded wire mesh factory

Steel Welded Wire Mesh Factory A Comprehensive Overview

In the modern industrial landscape, the demand for robust and reliable materials is paramount, particularly in construction, agriculture, and various manufacturing sectors. Among these materials, steel welded wire mesh has emerged as a quintessential component, owing to its strength, versatility, and efficiency. This article examines the intricate process behind the production of steel welded wire mesh and its applications across different industries.

Understanding Steel Welded Wire Mesh

Steel welded wire mesh is composed of longitudinal and transverse wires that are electrically welded at the intersections. This method ensures a strong bond at every intersection, making the structure resilient and capable of bearing substantial weight. The mesh is produced in various sizes and gauges, providing flexibility for numerous applications. Due to its strength and durability, welded wire mesh is often chosen over other materials for demanding projects.

The Manufacturing Process

The production of steel welded wire mesh begins with the selection of high-quality steel wires, which are then drawn to the desired diameter. The quality of the steel is crucial, as it directly impacts the performance of the final product. Once the wires are prepared, they are arranged in a grid format, either by hand or using automated machines.

The next step involves the welding process. Different techniques can be utilized, such as resistance welding or gas welding, but resistance welding is the most common in mesh production. In this method, electrical currents are passed through the wires, generating heat that fuses them at the intersection points. This process can be automated, allowing for consistent quality and faster production times.

steel welded wire mesh factory

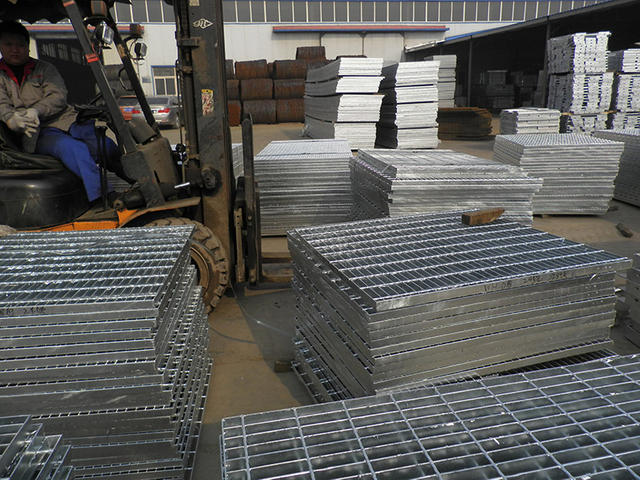

Once welded, the mesh is subjected to various finishing processes. Depending on the intended application, treatments such as galvanization or coating may be applied to enhance corrosion resistance and durability. These coatings can range from a layer of zinc to polymer-based finishes, offering additional protection against the elements.

Applications of Steel Welded Wire Mesh

Steel welded wire mesh finds a myriad of applications across various sectors. In construction, it is widely used as reinforcement in concrete slabs, walls, and pavements, providing added tensile strength and reducing the risk of cracking. The agricultural sector employs welded wire mesh for fencing, animal enclosures, and support for crop growth, highlighting its utility in livestock management and horticulture.

Moreover, this versatile mesh is favored in manufacturing for creating protective barriers, scaffolding, and containment structures, ensuring safety in various industrial environments. The mesh is also utilized in the production of custom products such as shelves, baskets, and furniture, showcasing its adaptability.

Conclusion

As industries continue to evolve and demand for durable materials increases, steel welded wire mesh stands out as a pivotal component in various applications. From construction and agriculture to manufacturing and beyond, its robust nature and versatility make it an essential material today. As manufacturers strive to enhance production processes and improve product quality, the steel welded wire mesh factory remains a cornerstone of modern industrial practices, contributing to safety, efficiency, and innovation across sectors.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025