Dec . 09, 2024 17:40 Back to list

6x6mm Steel Square Bars from Reliable Manufacturer for Versatile Applications

Understanding Steel Square Bar A Focus on 6x6mm Factory Outputs

Steel square bars are essential components in various construction and manufacturing processes. Among the many dimensions available, the 6x6mm steel square bar has gained popularity due to its versatility and strength. This article delves into the characteristics, applications, and manufacturing processes of steel square bars, focusing particularly on the 6x6mm dimension, and highlights the importance of factory production methods.

Characteristics of Steel Square Bars

Steel square bars are available in different sizes and grades, with the 6x6mm variant representing a balance of strength and workability. Typically made from carbon steel or alloy steel, square bars possess several inherent properties

1. High Strength Steel is renowned for its impressive tensile strength and resilience, making it suitable for structures that require robust materials. 2. Durability The chemical composition of steel allows it to withstand harsh environmental conditions, ensuring longevity. 3. Weldability Steel square bars can easily be welded, making them adaptable for various applications, including fabrication and repair work. 4. Versatility This dimension is suitable for both structural and decorative uses, offering a broad range of possibilities in diverse industries.

Applications of 6x6mm Steel Square Bars

The 6x6mm steel square bar finds applications across multiple sectors

1. Construction In the construction industry, these bars are often used for framing, supports, and reinforcements. Their strength and adaptability make them ideal for a variety of construction scenarios, including residential and commercial buildings. 2. Manufacturing Manufacturers employ steel square bars as raw materials for producing machinery, tools, and components. They can be cut, machined, or welded to create numerous finished products.

4. Art and Decoration With a polished finish, 6x6mm steel square bars can also be utilized in decorative applications, including modern art installations, sculptures, and functional decor items.

steel square bar 6*6mm factory

Manufacturing Process of Steel Square Bars

Producing steel square bars, especially the 6x6mm variety, involves several key steps. These processes are crucial to ensuring consistency, quality, and performance of the final product

1. Raw Material Selection The manufacturing process begins with the selection of high-quality steel, which is typically available in bulk forms. The choice of raw material affects the finished product’s strength and durability.

2. Forging and Rolling The selected steel is then subjected to processes such as forging and rolling. Through these methods, the steel is heated and shaped into square bars. The rolling process is particularly important as it helps achieve the desired dimensions, such as 6x6mm, while enhancing the mechanical properties of the steel.

3. Heat Treatment After the bars are formed, they often undergo heat treatment to improve their hardness and strength. This step is essential in achieving the required specifications for various applications.

4. Finishing The final stage involves finishing processes, such as grinding or polishing, to ensure that the steel square bars meet the necessary quality standards. This is particularly important for decorative applications where aesthetics play a significant role.

5. Quality Control Rigorous quality control measures are implemented throughout the production process to ensure that each batch of steel square bars meets industry standards. This includes dimensional checks, hardness testing, and surface inspections.

Conclusion

The 6x6mm steel square bar is a crucial material in both construction and manufacturing, exhibiting qualities that make it indispensable across various applications. As industries grow and evolve, the demand for reliable, high-quality materials continues to rise. Understanding the characteristics, applications, and manufacturing processes of steel square bars not only highlights their importance in today's market but also emphasizes the role of factories in producing these essential components. The future of steel square bars in various sectors seems bright, driven by innovation and the ongoing quest for efficient, durable materials.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

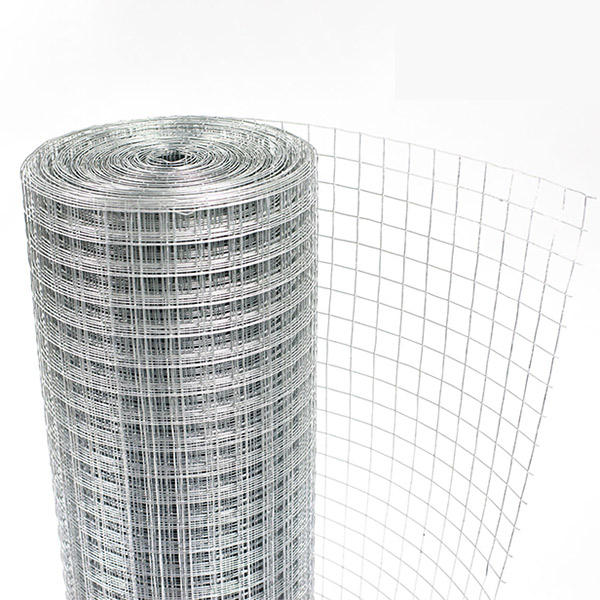

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025