Nov . 16, 2024 05:31 Back to list

steel construction reinforcement mesh supplier

The Importance of Steel Construction Reinforcement Mesh Suppliers

In the realm of construction, the demand for strong, durable, and reliable materials has never been more critical. One essential component in ensuring the structural integrity of buildings and infrastructure is reinforcement mesh. Steel construction reinforcement mesh suppliers play a pivotal role in the construction industry by providing high-quality products that enhance the strength and longevity of concrete structures.

Understanding Reinforcement Mesh

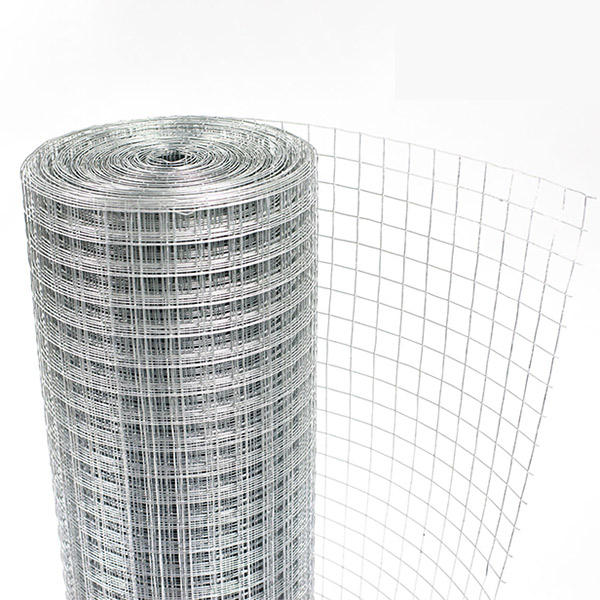

Reinforcement mesh, often composed of welded steel wire, is used extensively in concrete construction. Its primary function is to distribute loads and enhance the tensile strength of concrete, which is inherently weak under tension. The mesh acts as a backbone, providing the necessary support to withstand various stresses and strains, including those induced by environmental factors and heavy loads. Whether used in slabs, walls, or other structural elements, reinforcement mesh is crucial for ensuring safety and durability.

The Role of Suppliers

The role of steel construction reinforcement mesh suppliers is multifaceted. They are responsible for sourcing high-quality materials, ensuring that their products meet industry standards and specifications. Suppliers must provide a range of mesh types, including different grades and sizes, to cater to the diverse needs of construction projects. The ability to customize products further allows contractors to optimize their use of materials based on specific project requirements.

Reputable suppliers not only provide high-quality materials but also offer valuable expertise and support to construction companies. They can assist with technical specifications, detailing how different types of mesh might be suitable for various applications. This guidance is essential for contractors to make informed decisions that can impact the overall success of a project.

Quality Assurance

steel construction reinforcement mesh supplier

Quality assurance is a crucial aspect of a steel construction reinforcement mesh supplier's responsibilities. The integrity of the mesh determines the safety and performance of the concrete structures it supports. Suppliers must adhere to strict quality control processes, ensuring that every batch of mesh is tested and certified before it reaches the construction site. This involves regular inspections, compliance with national and international standards, and maintaining a robust supply chain to avoid any variations in quality.

The Importance of Local Suppliers

Choosing local suppliers can be beneficial for construction projects. Local suppliers have a better understanding of regional building codes, environmental regulations, and market dynamics. They often provide faster delivery times and can respond swiftly to urgent orders, which is crucial in a fast-paced construction environment. Furthermore, fostering relationships with local suppliers can lead to better communication and collaboration, resulting in smoother project execution.

Sustainability and Innovation

As the construction industry moves towards more sustainable practices, steel construction reinforcement mesh suppliers must also adapt. Many suppliers are now focusing on eco-friendly processes, sourcing materials from sustainable sources, and implementing recycling programs. Additionally, innovations in mesh design, such as the development of stronger and lighter materials, contribute to more efficient use of resources and enhanced performance of structures.

Conclusion

In conclusion, steel construction reinforcement mesh suppliers are a vital cog in the construction industry machinery. Their commitment to quality, expertise in materials, and ability to provide timely support significantly influence the outcome of construction projects. As the demand for high-quality and sustainable construction materials continues to grow, these suppliers will play an increasingly important role in shaping the built environment. By partnering with reputable suppliers, construction companies can ensure the strength, safety, and longevity of their projects, ultimately contributing to the overall advancement of infrastructure development.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025