Oct . 31, 2024 10:47 Back to list

standard welded wire mesh size factories

Understanding Standard Welded Wire Mesh Sizes and Their Factories

Welded wire mesh is a versatile product used across various industries, including construction, agriculture, and manufacturing. Its strength and durability make it ideal for a wide range of applications, from reinforcing concrete to providing security in fencing. Understanding the standard sizes and the manufacturing processes of welded wire mesh is essential for sourcing the right product for your needs.

What is Welded Wire Mesh?

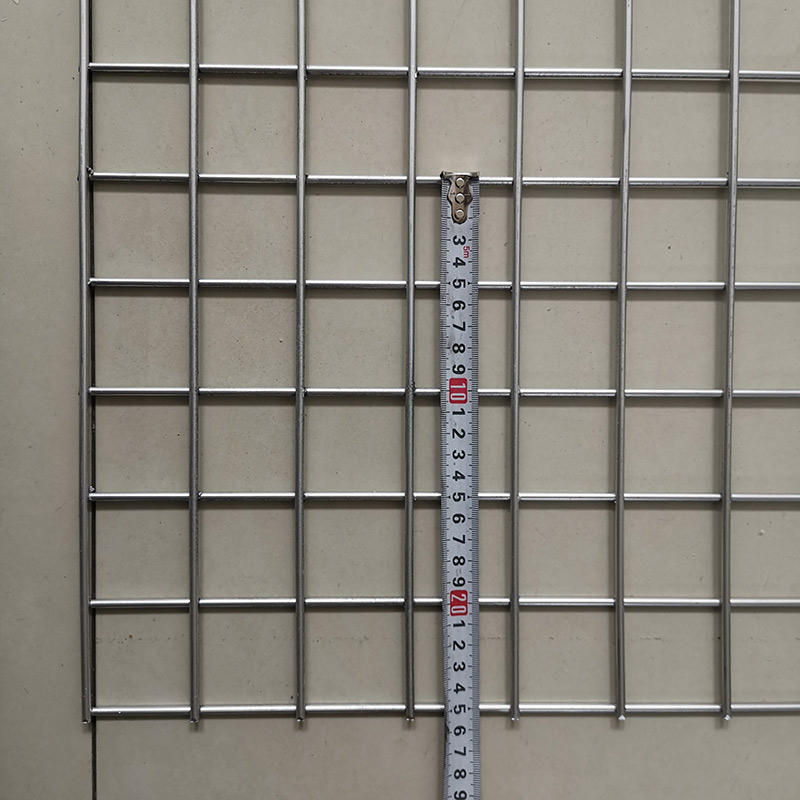

Welded wire mesh consists of a series of wires that are welded together at intersections, creating a grid-like pattern. These meshes are made from high-quality steel and can be coated with galvanization to enhance their resistance to corrosion. The design can vary in mesh size, wire diameter, and spacing, depending on the intended application.

Standard Sizes of Welded Wire Mesh

Welded wire mesh comes in various standard sizes to accommodate different projects and specifications. The mesh size is typically measured in inches, referring to the space between the wires. The common mesh openings include 1x1 inch, 2x2 inches, and 4x4 inches, among others. The thickness of the wires also varies, usually ranging from 14 to 6 gauge.

Commonly used sheet sizes include

1. 2 ft x 4 ft 2. 3 ft x 6 ft 3. 4 ft x 8 ft 4. 5 ft x 10 ft

While these dimensions are standardized, many manufacturers also offer customized solutions to meet specific project requirements. Whether it's for a small home fence or extensive construction reinforcement, choosing the right size is crucial for optimal performance.

The Manufacturing Process

standard welded wire mesh size factories

Welded wire mesh is produced using advanced manufacturing techniques to ensure quality and durability

. The process typically involves several key steps1. Wire Drawing High-quality steel rods are drawn through a series of dies to produce the required wire gauge.

2. Welding The wires are then arranged into grids and welded at intersections using automated welding machines. The welding process is critical for ensuring the strength and integrity of the mesh.

3. Coating To enhance corrosion resistance, the welded wire mesh can undergo galvanization, where it is coated in a layer of zinc. This step is particularly important for outdoor applications, where exposure to moisture can lead to rust and deterioration.

4. Cutting and Packing Once the welded wire mesh is completed, it is cut into standard sizes or customized dimensions, then carefully packed for shipping.

Choosing the Right Factory

When sourcing welded wire mesh, it's essential to partner with a reputable manufacturer. Look for factories that adhere to industry standards and possess certifications. A quality factory will offer transparency regarding their production processes and provide samples or product specs upon request.

Moreover, consider the factory’s production capacity and lead times, especially if you have a tight project schedule. An efficient supplier should be capable of meeting both standard requirements and customized orders promptly.

Conclusion

Welded wire mesh serves as a crucial material in numerous sectors, emphasizing the importance of selecting the appropriate size and quality for your specific needs. Understanding standard sizes, the manufacturing process, and choosing the right factory will ensure your project is successful and meets the necessary standards. Whether for security, construction, or other applications, welded wire mesh remains a reliable and essential material in modern industry.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025