Dec . 12, 2024 10:30 Back to list

standard welded wire mesh size

Understanding Standard Welded Wire Mesh Sizes

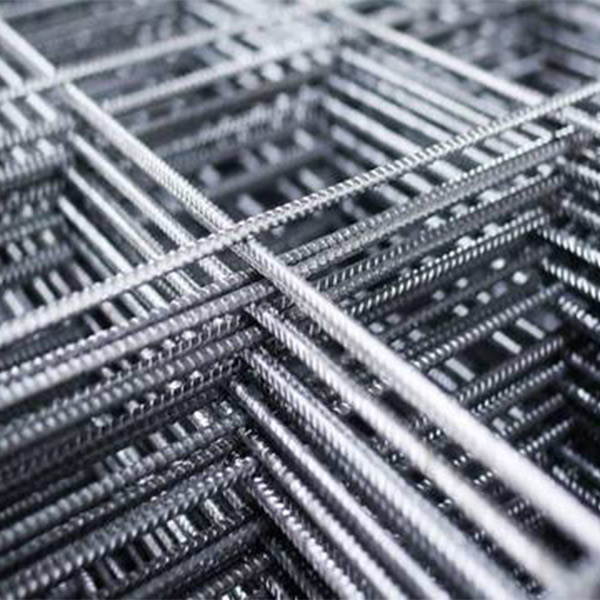

Welded wire mesh, a versatile and widely used construction material, is made from high-quality steel wires that are welded together at their intersections. It plays a critical role in various applications such as fencing, reinforcement, safety barriers, and even decorative elements. One of the key factors influencing its effectiveness and suitability for a particular project is the size of the mesh. In this article, we will delve into the importance of standard welded wire mesh sizes, their typical dimensions, and the factors to consider when selecting the right size for your needs.

Typical Sizes of Welded Wire Mesh

Welded wire mesh is available in a variety of sizes, which are generally categorized by the gauge of wire used, the spacing between the wires, and the overall dimensions of the rolls or sheets. Commonly, wire gauges can range from 6 to 12, with lower numbers indicating thicker wires. This thickness affects the strength and durability of the mesh, making it suitable for heavier load applications at lower gauges and lighter uses at higher gauges.

The mesh openings—the space between the wires—also vary widely. Standard sizes include 1-inch, 2-inch, and 4-inch openings, but custom sizes can also be manufactured to meet specific project requirements. The choice of mesh opening is critical as it determines the amount of material or load that can be supported, the type of animals that can be contained within fencing applications, and the visibility through the mesh in decorative uses.

Factors Influencing Mesh Size Selection

1. Application The intended use of the welded wire mesh is the primary factor influencing size selection. For example, a garden fence to keep small animals out might require a 2-inch mesh opening, while a construction site might need a stronger, closely spaced mesh to prevent debris from falling.

2. Load Requirements Welded wire mesh can provide different levels of support based on the wire gauge and mesh size. Heavier loads will necessitate a thicker gauge and possibly smaller openings to ensure adequate strength.

standard welded wire mesh size

3. Environmental Conditions Exposure to moisture, chemicals, or extreme temperatures can affect the longevity of the welded wire mesh. Understanding the environment in which it will be used is essential to selecting a size and coating that withstands these conditions.

4. Aesthetic Considerations When installed in a more visible area, such as a garden or residential fencing, the appearance of the wire mesh becomes crucial. Smaller openings and thinner wires may be preferred for a more delicate look, while thicker wires and larger openings may have a more industrial appearance.

5. Local Regulations Certain building codes or regulations may dictate specific sizes or types of welded wire mesh for safety or zoning purposes. It’s important to consult local guidelines before making a purchase.

Benefits of Standardization

One of the advantages of standard welded wire mesh sizes is that they offer consistency in quality and performance. Builders and contractors can easily source materials that meet their needs without having to deal with custom manufacturing, which can delay projects and increase costs. Standard sizes are also beneficial for inventory management, allowing suppliers to stock commonly requested sizes, thus ensuring a steady supply for contractors and DIY enthusiasts.

Moreover, standardized sizes ensure compatibility with various accessories and installation systems, minimizing the risk of errors during installation. This can be particularly beneficial in large-scale projects where multiple contractors may be involved.

Conclusion

In summary, selecting the appropriate size of welded wire mesh is crucial for the success of any project. By understanding the available sizes and their respective applications, along with factors such as load requirements and environmental conditions, one can make informed decisions that contribute to both the functionality and aesthetics of a construction project. Adhering to standardized sizes can streamline the procurement process, ensuring availability and compatibility, thereby facilitating smoother project execution. Whether for fencing, reinforcement, or decorative purposes, the right mesh size can make all the difference.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025