Jul . 26, 2024 12:59 Back to list

Specifications and Applications of Black Annealed Wire for Various Industrial Uses and Projects

Understanding Black Annealed Wire Specifications

Black annealed wire is a versatile material used in various industries, particularly in construction, manufacturing, and agriculture. The specifications for black annealed wire are critical to ensuring that the wire meets the required standards for strength, flexibility, and other mechanical properties. This article delves into the essential aspects of black annealed wire specifications, its manufacturing process, and its applications.

What is Black Annealed Wire?

Black annealed wire is a type of wire that has undergone an annealing process, which involves heating the wire to a specific temperature and then allowing it to cool slowly. This process alters the internal structure of the wire, improving its ductility and making it less brittle. The term black refers to the wire's surface, which is often coated with a layer of black oxide due to the annealing process, giving it a matte finish.

Key Specifications

1. Material Composition Black annealed wire is typically made from low-carbon steel, which contributes to its excellent ductility and malleability. The carbon content usually ranges from 0.05% to 0.25%, ensuring a good balance between strength and flexibility.

2. Diameter The diameter of black annealed wire can vary depending on its intended use. Common sizes range from 0.2 mm to 5 mm. The required diameter is determined by the application's specific strength and flexibility needs.

3. Tensile Strength The tensile strength of black annealed wire is a crucial specification, as it indicates how much force the wire can withstand before breaking. Typically, black annealed wire has a tensile strength ranging from 350 MPa to 600 MPa, depending on the wire's diameter and the specific treatment it has undergone.

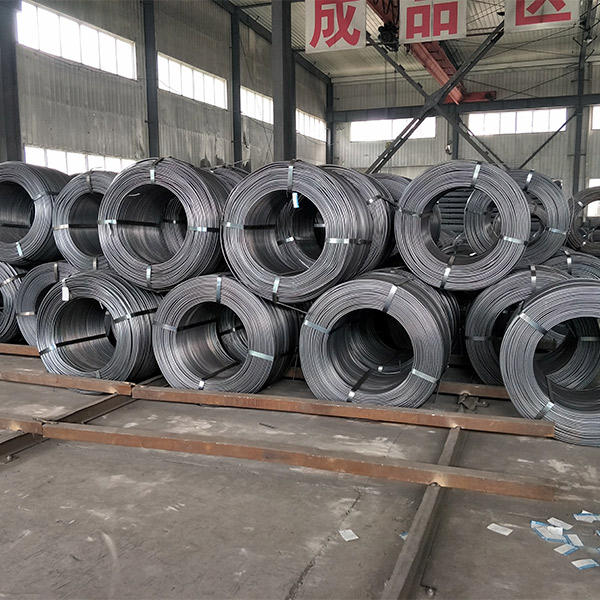

black annealed wire specification

4. Elongation Elongation measures how much the wire can stretch before breaking, which is essential for applications that require flexibility. Black annealed wire usually exhibits elongation values of around 10% to 25%, making it suitable for tasks that require bending or twisting.

5. Surface Treatment The surface of black annealed wire is typically free from rust and other impurities, although the black oxide layer adds a degree of corrosion resistance. However, additional treatments may be applied for specific environments, including galvanization or coating with protective materials.

Manufacturing Process

The manufacturing process of black annealed wire involves several steps. Initially, wire rods are drawn to the desired diameter through a series of dies. This drawing process increases the wire's tensile strength. After drawing, the wire undergoes the annealing process, where it is heated and then cooled. This step is crucial as it enhances ductility and reduces internal stresses. Finally, the wire is wound into coils and inspected to ensure it meets the necessary specifications.

Applications

Black annealed wire is widely used in various applications. In the construction industry, it is often utilized for tying rebar, fencing, and other structural applications. In agriculture, black annealed wire serves as binding material for crops and securing various agricultural products. Furthermore, it is also employed in the manufacturing of crafts, springs, and wire mesh.

Conclusion

Understanding the specifications of black annealed wire is vital for industries that rely on this material for their operations. With its excellent strength and flexibility properties, combined with its cost-effectiveness, black annealed wire continues to be a preferred choice in many applications. By adhering to strict specifications, manufacturers can ensure that their products meet the demands of various sectors, fostering efficiency and longevity in their use.

-

Chain Link Fence - Anping County Puersen | Durable, Versatile Fencing

NewsAug.15,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable Security&Wire Mesh

NewsAug.15,2025

-

Chain Link Fence: Durable & Versatile Security Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.15,2025

-

Chain Link Fence-Durable&Versatile|Anping County Puersen

NewsAug.15,2025

-

Welded Wire Mesh for Industry: Factory Supplier of Quality Mesh

NewsAug.15,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable, Versatile, Reliable Fencing Solution

NewsAug.14,2025