Jul . 25, 2024 06:45 Back to list

Specification Guide for Black Annealed Wire Manufacturing Standards in China and Their Applications

Understanding China Black Annealed Wire Specifications

Black annealed wire is a type of wire that has undergone a specific heat treatment process, known as annealing, to enhance its properties. Primarily produced in China, this wire is widely utilized across various industries due to its unique characteristics, including ductility, tensile strength, and corrosion resistance. The specifications of black annealed wire can vary based on its intended application, and understanding these specifications is crucial for selecting the right type of wire for a specific use.

What is Black Annealed Wire?

Black annealed wire is made from low carbon steel and is characterized by its dark appearance. The annealing process involves heating the wire to a high temperature and then allowing it to cool slowly, which helps to relieve internal stresses and improve the microstructure of the steel. The result is a wire that is much softer and more pliable than its non-annealed counterparts, making it suitable for various applications that require flexibility and ease of handling.

Key Specifications

1. Material and Grade The most common material used for black annealed wire is low carbon steel, often specified by standards such as ASTM A106 and ASTM A313. The wire is available in different grades, with common designations including ST37, ST52, or equivalent grades.

2. Diameter Black annealed wire is available in a variety of diameters, typically ranging from 0.5 mm to 5.0 mm. The choice of diameter often depends on the specific application, with thicker wires being used for heavier duty tasks and thinner wires for lighter applications.

3. Tensile Strength The tensile strength of black annealed wire generally ranges from 350 to 600 MPa. This property is crucial for applications where the wire is subjected to stress, such as in construction, fencing, and manufacturing.

china black annealed wire specification

4. Elongation The elongation percentage of black annealed wire can vary, but it typically falls between 15% to 25%. A higher elongation percentage indicates better ductility, allowing the wire to be stretched without breaking.

5. Coating While the term black refers to its uncoated state, black annealed wire can also be coated with other materials for enhanced protection against corrosion. Some common coatings include polyethylene, galvanized, and PVC, which can significantly extend the wire's lifespan, particularly in outdoor applications.

Applications

The uses of black annealed wire are diverse and span several industries. It is commonly used in

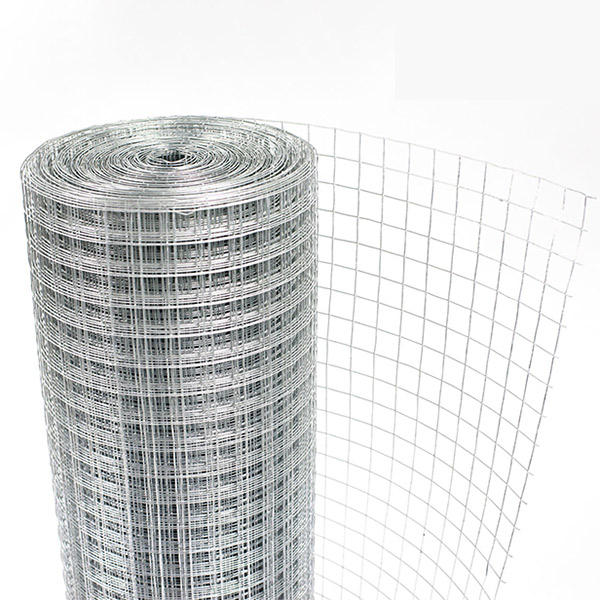

- Construction For tie wire, binding, and reinforcing purposes. Its flexibility allows it to be easily bent and shaped as needed. - Agriculture Used for fencing, tying, and securing plants. - Manufacturing In the production of wire mesh, springs, and other metal components. - Crafting and DIY Projects Due to its malleability, it is favored by artisans and hobbyists for various creative projects.

Conclusion

When selecting black annealed wire, it is essential to consider its specifications carefully to ensure it meets the requirements of the intended application. The properties of black annealed wire, shaped by the annealing process and defined by its diameter, tensile strength, and elongation percentage, make it a versatile choice in many fields. As industries continue to evolve, the demand for reliable and high-quality black annealed wire from China remains strong, highlighting its importance in global manufacturing and construction sectors. Understanding these specifications will not only help users make informed decisions but also ensure optimal performance and longevity in their applications.

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025