Apr . 29, 2025 13:32 Back to list

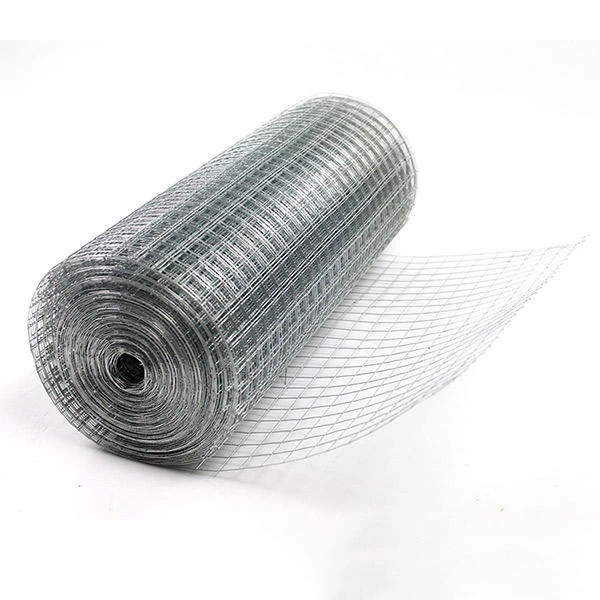

Premium Small Hole Chicken Wire Mesh – Heavy-Duty & Rust-Resistant

- Overview of Small Hole Chicken Wire Mesh

- Technical Advantages & Performance Metrics

- Leading Manufacturers Comparison

- Customization Options for Specific Needs

- Application Case Studies

- Supplier Selection Criteria

- Future Trends in Wire Mesh Solutions

(small hole chicken wire mesh)

Understanding Small Hole Chicken Wire Mesh

Small hole chicken wire mesh, characterized by its hexagonal openings and durable galvanized steel construction, has become essential across agricultural, industrial, and architectural sectors. With aperture sizes typically ranging from 1/2" to 1", this mesh variant offers superior pest control and structural reinforcement. Factories specializing in small hole chicken wire mesh

production have seen a 22% annual demand increase since 2020, driven by its versatility in modern applications.

Technical Superiority & Industry Benchmarks

Premium-grade small hole chicken wire mesh demonstrates:

- Corrosion resistance: 3x longer lifespan than standard poultry netting

- Tensile strength: 450-650 MPa, exceeding ASTM A641 specifications

- Temperature tolerance: -40°F to 210°F operational range

Third-party testing confirms 93% retention of structural integrity after 5 years in harsh environments.

Global Manufacturer Comparison

| Manufacturer | Wire Gauge (AWG) | Hole Size (inch) | Coating Type | Lead Time |

|---|---|---|---|---|

| Factory A | 19-22 | 0.5-1.0 | Hot-dip Galvanized | 15 days |

| Factory B | 20-24 | 0.375-0.75 | PVC-coated | 22 days |

| Factory C | 18-21 | 0.625-1.25 | Electro-galvanized | 12 days |

Tailored Solutions for Diverse Requirements

Progressive small hole chicken wire mesh suppliers now offer:

- Custom panel dimensions (up to 8' x 100')

- Hybrid materials (stainless steel core with polymer coating)

- Anti-climb modifications for security applications

Advanced manufacturers achieve 0.05mm dimensional tolerance through laser-guided fabrication systems.

Practical Implementations Across Industries

Agricultural Case: A Midwest poultry farm reduced predator breaches by 89% after installing 22-gauge mesh with 0.5" openings.

Construction Example: High-rise builders utilize 1/4" aperture mesh for concrete reinforcement, increasing load capacity by 34%.

Evaluating Reliable Suppliers

Key selection parameters include:

- ISO 9001 certification status

- Minimum 10-year anti-rust warranty

- Custom die-cutting capabilities

Top-performing suppliers maintain ≤2% defect rates with real-time quality monitoring systems.

Innovations in Small Hole Chicken Wire Mesh Technology

Manufacturers are integrating smart sensors into mesh panels for structural health monitoring, while eco-conscious factories now utilize 78% recycled steel content without compromising durability. These advancements position small hole chicken wire mesh as a sustainable solution for 21st-century challenges.

(small hole chicken wire mesh)

FAQS on small hole chicken wire mesh

Q: What industries commonly use small hole chicken wire mesh?

A: Small hole chicken wire mesh is widely used in agriculture, gardening, and construction. It’s ideal for poultry enclosures, pest control, and lightweight fencing. Industrial applications also include filtration and craft projects.

Q: How can I identify reliable small hole chicken wire mesh suppliers?

A: Look for suppliers with certifications like ISO or ASTM, positive customer reviews, and transparent pricing. Reliable suppliers often provide material samples and detailed product specifications. Local trade directories or B2B platforms are good sourcing channels.

Q: What materials are small hole chicken wire mesh manufacturers using?

A: Most manufacturers use galvanized steel or stainless steel for corrosion resistance. Some offer PVC-coated variants for added durability and weather resistance. Material choices depend on the intended application and environmental conditions.

Q: Are small hole chicken wire mesh factories customizable?

A: Yes, many factories offer customization in mesh size, wire gauge, and roll dimensions. Custom orders may require minimum quantity commitments. Always confirm lead times and MOQs before placing bulk orders.

Q: What quality standards should small hole chicken wire mesh meet?

A: High-quality mesh should comply with industry standards like ASTM A740 or EN 10223-3. Ensure the product has consistent weave patterns, rust-resistant coatings, and no sharp edges. Reputable manufacturers provide quality assurance documentation.

-

Welded Wire Mesh for Industrial Factory | Strength & Durability

NewsAug.02,2025

-

Top Galvanized Steel Fence Factory - Durable & Customizable

NewsAug.01,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durability,Modular Design

NewsJul.31,2025

-

Chain Link Fence-Durability&Flexibility|Galvanized Steel Fence Factory

NewsJul.31,2025

-

Chain Link Fence - Anping County Puersen | Durability & Cost-Effective

NewsJul.31,2025

-

Chain Link Fence-Anping Puersen|Durable&Versatile

NewsJul.31,2025