Nov . 14, 2024 16:12 Back to list

sl72 welded wire mesh factory

The SL72% Welded Wire Mesh Factory Innovation in Construction Reinforcement

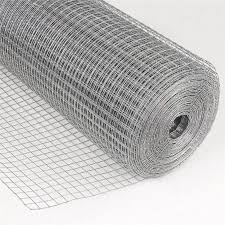

In the modern construction industry, the demand for high-quality materials is at an all-time high. Among these materials, welded wire mesh plays a crucial role in enhancing the structural integrity of various building projects. The SL72% welded wire mesh factory stands out as a leading manufacturer of this essential resource. With its focus on quality, innovation, and sustainability, the factory has carved a niche for itself in the competitive landscape of construction materials.

Understanding Welded Wire Mesh

Welded wire mesh is a type of reinforcing material made from intersecting wires that are welded together at their junctions. It is available in various sizes and specifications to suit a wide range of construction applications, including slabs, walls, and foundations. The SL72% specification refers to a specific arrangement of the mesh, designed to provide optimal strength and support for concrete structures. This innovative design means that it can effectively distribute loads and reduce the likelihood of cracking, making it an indispensable component in modern construction.

State-of-the-Art Manufacturing Process

At the heart of the SL72% welded wire mesh factory lies a commitment to technological advancement. The manufacturing process begins with high-quality steel, known for its strength and durability. This steel is carefully processed, ensuring that it meets the stringent standards required for construction. The factory utilizes automated machinery that provides precision in cutting, shaping, and welding the wire. This automation not only increases efficiency but also ensures consistent quality across all products.

Moreover, the factory emphasizes quality control at every stage of production. From the initial selection of raw materials to the final inspection of finished products, each step is meticulously monitored. This rigorous quality assurance process guarantees that the welded wire mesh produced at the SL72% factory meets international standards, thereby providing clients with confidence in the safety and reliability of their construction materials.

Commitment to Sustainability

sl72 welded wire mesh factory

In today’s world, sustainability is more important than ever. The SL72% welded wire mesh factory recognizes this and is dedicated to minimizing its environmental impact. The factory implements eco-friendly practices in its operations, from sourcing raw materials to production methods. For instance, the recycling of scrap steel is a significant part of the manufacturing process, reducing waste and conserving resources.

Additionally, the factory invests in energy-efficient technologies that lower carbon emissions. By optimizing its operations, the factory not only contributes to environmental conservation but also provides cost savings that can be passed on to its customers. This commitment to sustainability strengthens the factory's reputation as a responsible player in the construction industry.

Customer-Centric Approach

Understanding the unique needs of each client is paramount for the SL72% welded wire mesh factory. The factory prides itself on its customer-centric approach, offering tailored solutions that meet specific project requirements. Whether it's a large commercial building or a small residential project, the factory is equipped to provide expert advice and support throughout the planning and execution phases.

The factory's dedicated customer service team ensures timely communication and delivery, further solidifying its relationships with contractors and builders. By fostering these partnerships, the SL72% welded wire mesh factory not only facilitates successful projects but also contributes to the overall growth of the construction industry.

Conclusion

The SL72% welded wire mesh factory exemplifies excellence in the production of welded wire mesh, combining advanced technology, stringent quality control, and a commitment to sustainability. As the construction industry continues to evolve, the factory remains poised to meet the increasing demands for reliable reinforcement materials. With an unwavering focus on quality and customer satisfaction, the SL72% factory is set to play a pivotal role in shaping the future of construction, ensuring that structures are not only strong but also built to last.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025