Nov . 10, 2024 07:11 Back to list

Supplier for SL72 SL82 SL92 Mesh Products with Competitive Quality and Pricing

SL72, SL82, and SL92 Mesh Suppliers A Comprehensive Overview

In the textile and industrial sectors, mesh materials play a critical role in various applications, from filtration systems to architectural designs. Among the different types of mesh, SL72, SL82, and SL92 are notable for their unique properties and wide-ranging uses. This article delves into these mesh types, focusing on the significance of reputable suppliers in ensuring quality and performance.

What are SL72, SL82, and SL92 Mesh?

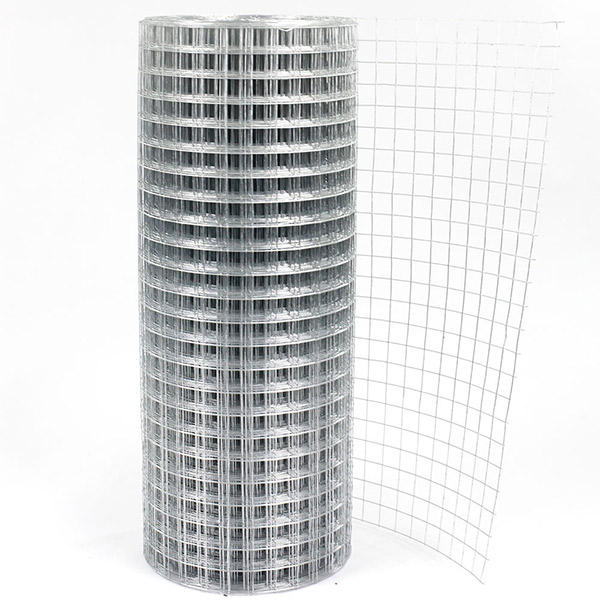

SL72, SL82, and SL92 mesh refer to specific grades of woven wire mesh that vary in their specifications, including wire diameter, mesh count, and material composition. Each type has distinct characteristics that cater to different industry needs

1. SL72 Mesh This mesh type is typically constructed with finer wire diameters and a larger mesh count, making it ideal for applications requiring fine filtration. SL72 mesh is commonly used in sieving, filtering, and sorting processes in industries such as food processing, pharmaceuticals, and chemicals. Its strength and versatility make it a preferred choice for industrial applications.

2. SL82 Mesh SL82 mesh offers a balance between durability and filtration performance. It has a slightly thicker wire than SL72, making it suitable for applications requiring both strength and dispersion of finer particles. This type of mesh finds extensive use in the construction industry, particularly for reinforcing structures. Additionally, its applications extend to agricultural uses, such as crop protection and animal enclosures.

3. SL92 Mesh This variant is recognized for its robust construction and larger overall openings, which facilitate drainage and air circulation. SL92 mesh is often used in architectural applications, such as facades or as protective barriers, where aesthetics and functionality intersect. It also serves various industrial applications that require high flow rates for liquids or gases.

The Importance of Quality Suppliers

sl72 sl82 sl92 mesh supplier

A reliable supplier is instrumental in sourcing high-quality SL72, SL82, and SL92 mesh. The demand for these products spans numerous industries, and the integrity of the mesh can significantly impact operational efficiency and safety. Here are some factors to consider when selecting a mesh supplier

1. Material Quality The quality of materials used to manufacture the mesh affects its durability and functionality. Reputable suppliers source high-grade stainless steel or other corrosion-resistant materials, ensuring that their mesh withstands harsh environments and extends product lifespan.

2. Manufacturing Standards It is essential to choose suppliers who adhere to international manufacturing standards. High-quality mesh is produced using advanced techniques and technology, which guarantees uniformity in mesh sizes and wire spacing, resulting in consistent performance across batches.

3. Customization Options Industries often require specific mesh configurations to meet their unique needs. Top suppliers offer customization options, allowing clients to specify dimensions, mesh types, and materials to align with their operational requirements.

4. Technical Support A competent supplier should also provide technical support and guidance. This expertise can be invaluable in optimizing mesh selection for specific applications, ensuring customers make informed decisions.

5. Reputation and Reviews Researching a supplier's reputation and customer reviews can provide insights into their reliability and service quality. Testimonials from other businesses can shed light on the supplier's ability to meet deadlines, respond to inquiries, and uphold product quality.

Conclusion

In conclusion, SL72, SL82, and SL92 mesh are integral to numerous industrial and architectural applications, each offering distinct benefits depending on the specific needs. Partnering with a reliable and experienced mesh supplier is crucial in ensuring that you obtain high-quality products tailored to your requirements. In an ever-evolving industrial landscape, the right supplier can make all the difference in achieving operational success and maintaining product standards. As demand for these mesh types continues to grow, the focus on quality, customization, and support will remain paramount for businesses seeking to enhance their operations.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025