Nov . 24, 2024 06:29 Back to list

sl72 sl82 sl92 mesh factories

The Role of SL72, SL82, and SL92 Mesh Factories in Modern Industry

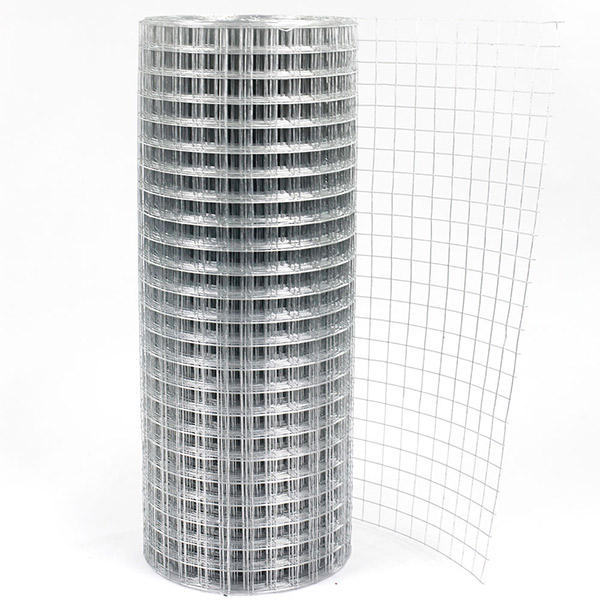

In the contemporary manufacturing landscape, mesh materials have become increasingly important across various sectors, including construction, agriculture, and industrial applications. Among the most notable mesh products are the SL72, SL82, and SL92 types, each with its distinct specifications and advantages, contributing significantly to the efficiency and durability of projects.

Mesh materials are produced through a systematic process that typically involves the weaving of wires into different patterns. The SL series mesh types, specifically SL72, SL82, and SL92, refer to different specifications regarding the wire diameter, spacing, and overall tensile strength, all of which play critical roles in their application effectiveness.

The Role of SL72, SL82, and SL92 Mesh Factories in Modern Industry

SL82 Mesh, on the other hand, offers a slightly different configuration that provides greater spacing while maintaining robust strength. This mesh type typically features an 8mm wire diameter with a spacing usually around 200mm. Its unique specifications allow it to be utilized effectively in applications requiring a balance between flexibility and strength. Its lightweight yet durable design makes it suitable for residential projects, especially in underpinning and foundation work, where the load distribution is critical.

sl72 sl82 sl92 mesh factories

Finally, the SL92 Mesh is distinguished by its thicker wires and larger spacing, commonly 10mm in diameter. This makes SL92 particularly suitable for applications demanding higher tensile strength. Its increased thickness translates to superior load-bearing capabilities, making it an ideal choice for industrial projects, including warehouses and heavy-duty pavements.

The production processes of SL72, SL82, and SL92 mesh in modern factories leverage advanced technologies, including automated weaving machines and precision cutting tools. Such advancements ensure uniformity in product quality and adherence to industry standards, ultimately leading to improved performance in practical applications.

Moreover, sustainability practices are increasingly integrated into the operations of these factories. As industries seek to minimize their environmental footprint, manufacturers are adapting their processes to recycle materials and reduce waste. This not only helps in conserving natural resources but also aligns with the growing demand for eco-friendly construction materials.

In conclusion, the SL72, SL82, and SL92 mesh factories play a pivotal role in contemporary manufacturing by providing essential components that enhance the safety, durability, and efficiency of construction projects. As industries evolve, the demand for such specialized materials will continue to grow, making these mesh varieties crucial to meeting modern engineering needs. With ongoing innovations in production methods and a commitment to sustainability, the future of SL mesh manufacturing looks promising and integral to the industries they serve.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025