Dec . 10, 2024 13:20 Back to list

sl52 sl62 sl72 sl82 reinforcement manufacturers

Understanding SL52, SL62, SL72, and SL82 Reinforcement Manufacturers

Reinforcement materials play a crucial role in the construction industry. They provide the necessary strength and durability needed for structures to withstand various forces and environmental conditions. Among the many types of reinforcement bars (rebars) available in the market, SL52, SL62, SL72, and SL82 are commonly used due to their unique properties and suitability for different applications. This article will explore these specific grades of reinforcement bars and the manufacturers that supply them.

What are SL52, SL62, SL72, and SL82?

SL52, SL62, SL72, and SL82 refer to specific grades of steel reinforcement bars. The designation typically indicates the yield strength and diameter of the bars, influencing their application in construction projects.

- SL52 Typically referring to a rebar with a nominal diameter of 12-16 mm and a yield strength of about 500 MPa, SL52 is commonly used in small to medium-sized structures. Its versatile nature makes it suitable for residential buildings, pavements, and foundations.

- SL62 A step up from SL52, SL62 rebars often have a diameter range of 16-20 mm and a similar yield strength of around 600 MPa. This makes them ideal for medium to large structures such as commercial buildings and bridges, where additional load-bearing capacity is vital.

- SL72 With increased diameter (20-25 mm) and a higher yield strength (approximately 700 MPa), SL72 rebars are preferred for larger and more complex constructions, including high-rise buildings and industrial facilities.

- SL82 These rebars can have diameters exceeding 25 mm and a yield strength of up to 800 MPa. SL82 is typically used for heavy-duty applications, including bridges, tunnels, and large-scale infrastructure projects where high tensile strength is critical.

The Importance of Quality in Manufacturing

The reliability of any construction project hinges on the quality of the materials used. This is particularly true for reinforcement bars, where substandard materials can lead to structural failure. Consequently, manufacturers of SL52, SL62, SL72, and SL82 rebars must adhere to stringent international standards and regulations.

sl52 sl62 sl72 sl82 reinforcement manufacturers

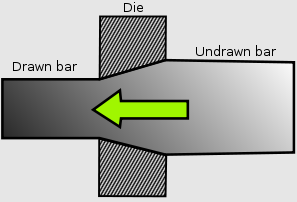

Quality assurance begins with the selection of raw materials. Leading manufacturers often utilize high-grade steel with minimal impurities. The manufacturing process itself typically involves advanced techniques, including hot rolling and controlled cooling, to ensure that the rebars meet the specific mechanical properties demanded by various codes and standards.

Top Manufacturers in the Market

Several reputable manufacturers specialize in producing SL52, SL62, SL72, and SL82 rebars. Among them, the following stand out

1. Tata Steel A global leader in steel production, Tata Steel offers a range of high-quality reinforcement bars compliant with international standards, ensuring durability and safety in construction.

2. ArcelorMittal Known worldwide, ArcelorMittal provides a comprehensive product range, including various grades of rebars tailored to meet the specific needs of construction projects.

3. Nucor Steel As one of the largest steel producers in the United States, Nucor focuses on environmentally sustainable manufacturing practices while maintaining high-quality standards for their reinforcement bars.

4. Steel Authority of India Limited (SAIL) One of India’s largest steel producers, SAIL manufactures a variety of steel products, including SL-grade reinforcement bars, ensuring compliance with local and international standards.

Conclusion

As the construction industry continues to evolve, the demand for high-quality reinforcement bars like SL52, SL62, SL72, and SL82 will only grow. The manufacturers that excel in producing these materials will be crucial in ensuring the integrity and longevity of future construction projects. By prioritizing quality and innovation, these companies help pave the way for safer, more durable structures that meet the demands of modern society.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Corrosion Resistance&Structural Integrity

NewsSep.01,2025

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025