Dec . 05, 2024 08:16 Back to list

Comparative Analysis of SL52 SL62 SL72 SL82 Reinforcement Manufacturers and Their Products

Understanding SL52, SL62, SL72, and SL82 Reinforcement Manufacturers

Reinforcement bars, commonly known as rebar, play a critical role in construction, providing the tensile strength necessary to bolster concrete structures. Among the various classifications of rebar available in the market, the SL series—SL52, SL62, SL72, and SL82—are significant due to their unique properties and applications. This article delves into these designations, their manufacturers, and their implications for the construction industry.

The Significance of SL Series Rebar

The SL series represents a range of reinforcement bars that vary in diameter and yield strength. Typically, these bars are measured in millimeters, with SL52 being 5.2mm, SL62 at 6.2mm, SL72 at 7.2mm, and SL82 at 8.2mm in diameter. This classification allows engineers and builders to select the most appropriate rebar for specific applications, based on the structural requirements and load-bearing capacity of the project.

The numbers directly relate to the tensile strength of the bars, which is a critical factor in ensuring the integrity and safety of a structure. For instance, SL82 may be chosen for heavy-duty constructions such as bridges and high-rise buildings, where load demands are greater compared to residential structures that might utilize SL52 or SL62.

Manufacturers in the Reinforcement Bar Market

The demand for high-quality reinforcement bars has led to a proliferation of manufacturers worldwide. These companies vary in scale and specialization, from globally recognized brands to local firms, each contributing to the competitive landscape of the construction materials industry.

1. Global Leaders Major players like Tata Steel, ArcelorMittal, and Nucor have established a strong reputation for producing high-strength reinforcement bars, including those within the SL series. Their commitment to innovation and quality control ensures that their products meet international standards, which is vital for large-scale constructions.

2. Regional Manufacturers In addition to global giants, numerous regional manufacturers have emerged, particularly in markets like Asia and the Middle East. Companies such as JSW Steel in India and Ezz Steel in Egypt provide cost-effective reinforcement solutions tailored to local construction norms and requirements.

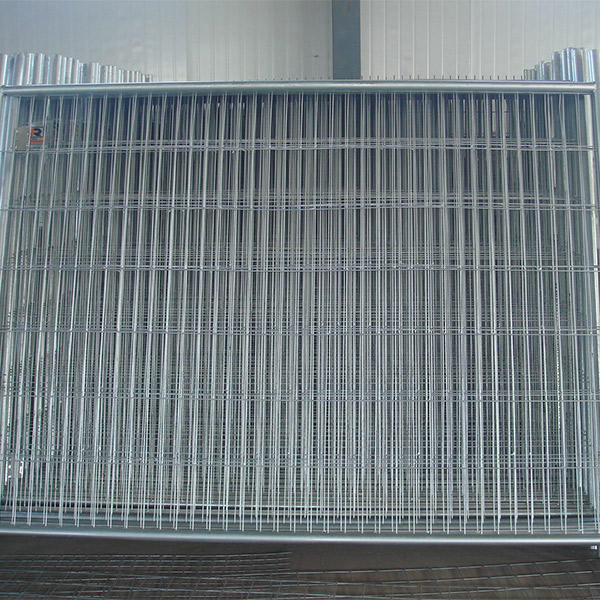

sl52 sl62 sl72 sl82 reinforcement manufacturers

3. Quality Assurance Manufacturers of SL52, SL62, SL72, and SL82 bars are often evaluated based on their adherence to quality standards. Certifications such as ISO or ASTM indicate that the rebar has undergone rigorous testing for durability and performance, ensuring that projects utilizing these materials are safe and reliable.

Benefits of Using SL Series Reinforcement

The diversity in the SL series allows engineers and architects to optimize their designs, effectively balancing strength, weight, and cost. Here are several benefits associated with using SL52, SL62, SL72, and SL82 reinforced bars

- Strength-to-Weight Ratio These rebar types offer excellent tensile strength while maintaining a relatively light weight. This property is particularly advantageous when designing large structures where excessive weight could pose logistical challenges.

- Improved Durability Higher-grade steel used in the SL series rebar enhances the longevity of concrete structures, particularly in environments exposed to harsh weather, chemicals, or high-stress conditions.

- Versatility The different specifications allow these bars to be utilized across a range of applications, from residential buildings to industrial complexes and infrastructure projects.

Conclusion

Reinforcement manufacturers of SL52, SL62, SL72, and SL82 bars are pivotal to the construction industry, providing essential materials that enhance the safety and longevity of buildings and infrastructure. The growth of this market reflects broader trends in construction technology and materials science, where innovation and quality assurance remain central. As the demand for sustainable and durable construction materials continues to rise, these manufacturers are poised to play an ever-important role in shaping the built environment of the future. By carefully selecting the appropriate type and grade of reinforcement, builders can achieve structural integrity that meets the challenges of modern construction demands.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025