Sep . 01, 2024 23:38 Back to list

High-Quality Reinforcement Solutions for SL52, SL62, SL72, and SL82 Manufacturers

Understanding SL52, SL62, SL72, and SL82 Reinforcement Bar Manufacturers

Reinforcement bars, commonly known as rebar, play a crucial role in construction, providing tensile strength and durability to concrete structures. In the world of construction materials, SL52, SL62, SL72, and SL82 refer to different grades and specifications of steel reinforcement bars that are widely used by manufacturers and builders. Understanding these specifications is essential for selecting the right materials for specific construction projects.

What are SL52, SL62, SL72, and SL82?

The designations SL52, SL62, SL72, and SL82 refer to the diameter and strength of the steel reinforcement bars. The 'SL' indicates that these bars are manufactured according to specific standards, while the numerals correspond to their nominal diameters measured in millimeters. For example, SL52 has a diameter of 16 mm, SL62 has a diameter of 20 mm, SL72 has a diameter of 25 mm, and SL82 has a diameter of 32 mm. Each type is designed to meet particular load-bearing requirements and environmental conditions, making them suitable for varying applications in construction.

Manufacturers of SL52, SL62, SL72, and SL82 Rebars

There are several manufacturers worldwide known for producing high-quality SL52, SL62, SL72, and SL82 reinforcement bars. These manufacturers adhere to stringent guidelines and standards ensuring that their products meet the required tensile strength, elongation, and yield strength. Some of the leading manufacturers specialize in producing a wide range of structural steel products, including various grades of rebar.

When choosing a manufacturer, it is important to consider factors such as certifications, quality control processes, and the ability to meet project timelines. Many manufacturers also offer customized solutions to meet specific engineering requirements, providing designers and builders with the flexibility needed for complex projects.

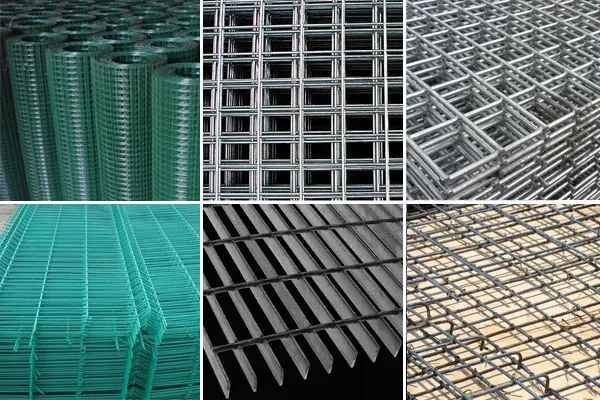

sl52 sl62 sl72 sl82 reinforcement manufacturers

Applications of SL Rebars

The applications of SL52, SL62, SL72, and SL82 are vast and varied. These reinforcement bars are predominantly used in reinforced concrete structures such as bridges, commercial buildings, industrial facilities, roads, and residential properties. Their high tensile strength makes them ideal for structures that need to withstand heavy loads and dynamic forces, such as seismic activity.

Additionally, the environmental conditions of a project can dictate the choice of rebar. For example, SL reinforcing bars with corrosion-resistant properties may be preferred in coastal areas where salt exposure is heightened. Manufacturers often offer different treatments and coatings to enhance the durability of their products, safeguarding against wear and weathering.

Quality Assurance and the Importance of Compliance

Quality assurance is paramount in the manufacture of SL52, SL62, SL72, and SL82 rebars. Reputable manufacturers conduct rigorous testing on their products to ensure compliance with national and international standards, such as the American Society for Testing and Materials (ASTM) and the European Committee for Standardization (CEN). This compliance not only guarantees the safety and performance of the materials but also enhances the longevity of construction projects.

In conclusion, selecting the right reinforcement bars is fundamental to the success of any construction endeavor. Understanding the specifications and applications of SL52, SL62, SL72, and SL82 is critical for engineers and builders alike. Collaborating with trusted manufacturers who can provide high-quality, reliable products will ultimately contribute to safer and more resilient structures in our built environment.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025