Nov . 10, 2024 08:01 Back to list

Manufacturers of Roll Welded Wire Mesh Products for Various Applications

Understanding Roll Welded Wire Mesh Factories

Roll welded wire mesh is a crucial component used across various industries, thanks to its versatility, strength, and durability. Its manufacturing process, typically undertaken in specialized factories, involves intricate techniques ensuring high-quality output. This article delves into the workings of roll welded wire mesh factories, exploring their significance, production processes, applications, and the future of this essential product.

What is Roll Welded Wire Mesh?

Roll welded wire mesh consists of intersecting wires that are welded together at their junctions. This creates a strong, continuous mesh that can be rolled for easy transport and installation. The mesh is available in various wire diameters, mesh sizes, and roll dimensions, making it suitable for diverse applications—from construction and agriculture to industrial and security uses.

The Manufacturing Process

The manufacturing of roll welded wire mesh typically involves several steps, designed to ensure the utmost precision and quality. The raw material, usually high-quality steel wire, is first processed to the desired diameter. The wires are then fed into a mesh welding machine where they are arranged in a grid pattern. Electrical resistance welding technology is commonly used in this process. This method allows for the wires to be joined together at their intersections without requiring additional materials, resulting in a robust and reliable product.

After welding, the mesh goes through various finishing processes, including cleaning and coating. The cleaning process removes any residues or contaminants that may have accumulated during manufacturing. Coating the mesh, often with galvanized or PVC materials, enhances its durability and protects it against rust and corrosion, extending its lifespan and usability.

Finally, the finished mesh is rolled into convenient sizes for shipping and handling. Factories often adhere to specific customer requirements regarding dimensions and specifications, ensuring a tailored product that meets diverse needs.

roll welded wire mesh factories

Applications of Roll Welded Wire Mesh

The applications of roll welded wire mesh are vast and varied. In the construction industry, it is widely used for reinforcing concrete structures, providing added strength and stability. The agricultural sector employs it for fencing, animal enclosures, and crop protection, helping to secure livestock and protect crops from pests.

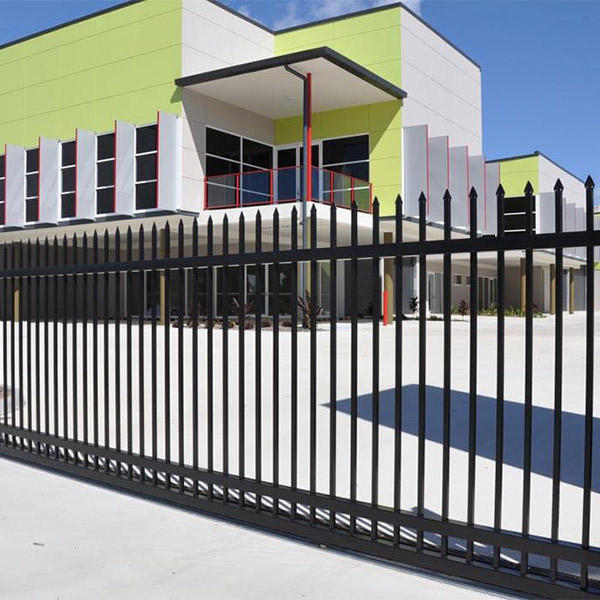

In the industrial realm, roll welded wire mesh is used in the production of barriers and safety fencing, protecting both equipment and personnel in various settings. Furthermore, it is an essential component in the manufacturing of various products, including furniture, storage racks, and wire forms.

Moreover, roll welded wire mesh finds applications in architectural designs, where it serves aesthetic and functional purposes. Its versatility allows architects to use it in facades, screens, and even as an artistic element in contemporary structures.

The Future of Roll Welded Wire Mesh

As industries evolve, so do the materials and processes utilized in their operations. Roll welded wire mesh factories are increasingly adopting automated technologies and innovative welding techniques to enhance production efficiency. This shift towards automation not only increases output but also improves precision and reduces waste.

Sustainability is another significant focus for future manufacturing practices. Factories are exploring environmentally friendly processes, such as recycling scrap metal and using eco-friendly coatings. This shift towards sustainable practices reflects a growing awareness of environmental conservation within the industry.

In conclusion, roll welded wire mesh factories play a vital role in producing a product that is not only essential for various applications but is also evolving with advancements in technology and sustainability practices. As industries continue to grow and innovate, the demand for high-quality roll welded wire mesh is expected to rise, ensuring that these factories remain a significant player in the manufacturing landscape.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025