Nov . 08, 2024 12:22 Back to list

Leading Manufacturers of High-Quality Reo Mesh for Construction Industry Applications

Understanding Reo Mesh Manufacturers A Comprehensive Insight

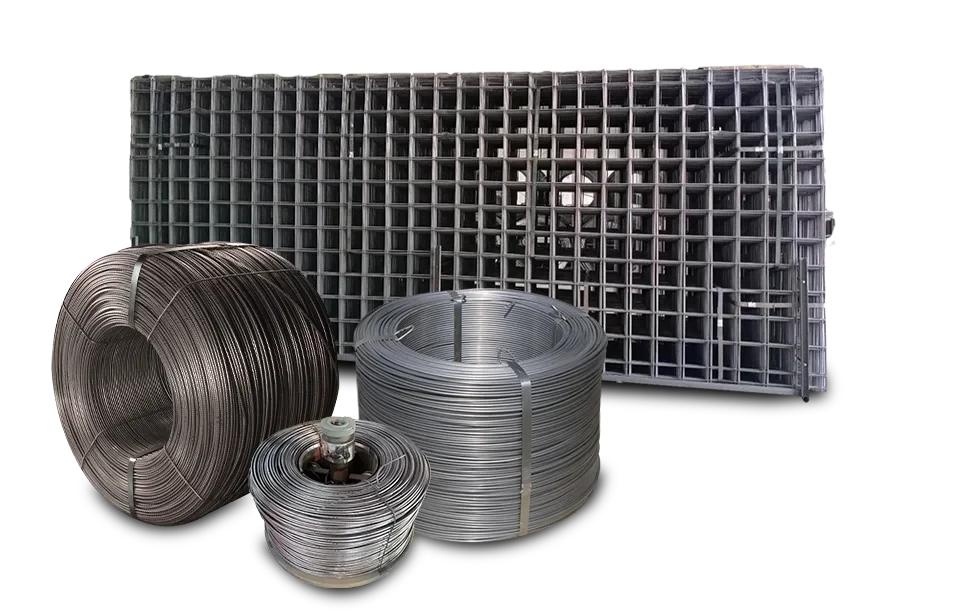

Reo mesh, or reinforcement mesh, plays a pivotal role in the construction industry, providing essential support and strength to concrete structures. As the demand for durable and robust buildings continues to rise, the role of reo mesh manufacturers has become increasingly significant. This article delves into the intricacies of the reo mesh manufacturing process, the qualities to look for in a reliable manufacturer, and the benefits of using high-quality reo mesh in construction projects.

What is Reo Mesh?

Reo mesh consists of a grid of steel bars or wires, usually welded together to form a stable framework. This framework reinforces concrete, imparting necessary tensile strength that concrete alone lacks. It is commonly used in various applications, including slabs, walls, and foundations, to ensure structural integrity. The mesh helps to prevent cracks and stress in concrete, thus prolonging the service life of structures and ensuring safety.

The Manufacturing Process of Reo Mesh

The manufacturing process of reo mesh involves several steps. Initially, high-quality steel is procured, as the strength and resilience of the final product rely heavily on the quality of the raw materials. The following are key stages in the manufacturing process

1. Cutting Steel Rods Steel rods are cut to specified lengths according to the design requirements of the mesh.

2. Welding The cut rods are arranged in a grid pattern, and automated welding machines fuse them at their intersections, creating a sturdy mesh.

3. Quality Control After the welding process, the created mesh undergoes rigorous quality control assessments. Factors such as weld integrity, mesh dimensions, and strength are scrutinized to ensure that the product meets industry standards.

4. Surface Treatment Depending on the intended use, surface treatments such as galvanization may be applied to enhance corrosion resistance, particularly for structures exposed to harsh environments.

5. Packaging and Distribution Once quality checks are completed, the finished reo mesh products are packaged and prepared for distribution to construction sites or retailers.

Choosing a Reliable Reo Mesh Manufacturer

When selecting a reo mesh manufacturer, several factors should be considered to ensure quality and reliability

reo mesh manufacturers

1. Quality Standards Look for manufacturers that adhere to international quality standards, such as ISO certifications. This ensures that their products are reliable and meet safety regulations.

2. Experience and Reputation Established manufacturers with a strong reputation in the industry can often deliver superior products. Research reviews and testimonials from previous clients to gauge their satisfaction.

4. Technological Advancement Manufacturers that utilize advanced technology in production are likely to produce more precise and durable products.

5. After-sales Support Reliable customer service and support can ensure that any issues arising post-purchase are addressed promptly, leading to a smoother project execution.

Benefits of High-Quality Reo Mesh

Investing in high-quality reo mesh provides multiple advantages for construction projects

- Increased Durability Quality reo mesh enhances the tensile strength of concrete structures, making them more resilient to stress and external forces.

- Cost-Effectiveness While high-quality reo mesh may come at a higher upfront cost, it saves money in the long run by reducing maintenance needs and extending the lifespan of structures.

- Safety Assurance Using reputable materials minimizes the risk of structural failures, ensuring safety for occupants and reducing liability concerns for builders.

- Sustainability High-quality materials typically result in fewer repairs and replacements, contributing to more sustainable construction practices.

Conclusion

In conclusion, the role of reo mesh manufacturers is integral to the construction industry. By understanding the manufacturing process, choosing the right supplier, and recognizing the benefits of high-quality products, builders can enhance the durability and safety of their structures. As the construction landscape continues to evolve, the importance of reliable and innovative solutions in reinforcement, such as reo mesh, will only continue to grow.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025