Oct . 12, 2024 22:52 Back to list

reo mesh manufacturer

The Rise of Reo Mesh Manufacturers Advancements and Applications

In the construction and manufacturing industries, innovation plays a crucial role in enhancing safety, durability, and efficiency. One such innovation is the use of Reo mesh, a vital component that has gained significant attention from manufacturers worldwide. This article delves into the importance of Reo mesh, explores its manufacturing process, and highlights its applications across various sectors.

What is Reo Mesh?

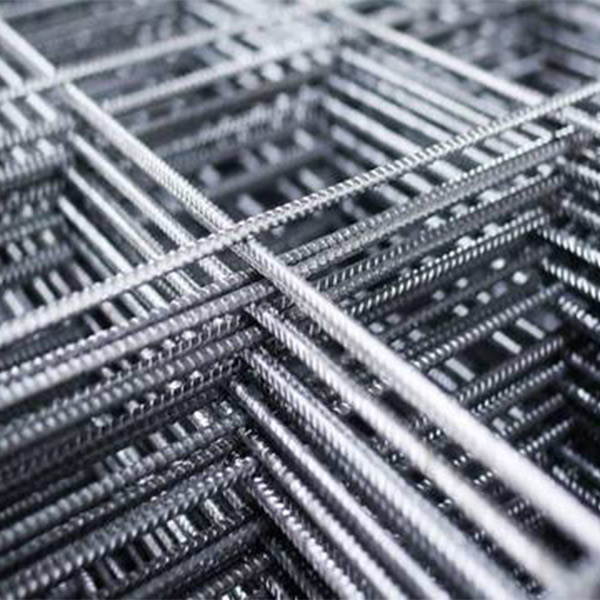

Reo mesh, commonly known as reinforcement mesh, is a grid-like structure made from reinforcing steel bars, typically used to enhance the tensile strength of concrete structures. The mesh is formed by welding together longitudinal and transverse bars, creating a robust framework that provides critical structural support in various construction applications. This product is essential for ensuring the longevity and stability of concrete elements, especially in load-bearing applications.

The Manufacturing Process

The manufacturing of Reo mesh involves several steps to ensure the highest quality and performance standards. Firstly, high-grade steel rods are sourced, and these rods undergo a rigorous quality inspection process to ensure they meet industry standards. The rods are then cut into specific lengths based on the design requirements of the mesh.

Next, the rods are arranged in a grid pattern, followed by the welding process where the bars are fused together at their intersections. This operation requires precision machinery, ensuring that the mesh is uniformly constructed for optimal strength. Post-manufacturing, the Reo mesh is often subjected to surface treatments such as galvanization to enhance corrosion resistance, extending its service life in harsh environments.

With advancements in technology, some manufacturers have begun integrating automated processes, which improve the speed and consistency of production. The use of computer-aided design (CAD) software allows for precise customization, enabling manufacturers to cater to specific project requirements efficiently.

Applications of Reo Mesh

reo mesh manufacturer

Reo mesh has a wide range of applications, making it indispensable in modern construction practices. One of its primary uses is in the reinforcement of concrete slabs, beams, and foundations. In residential, commercial, and industrial buildings, Reo mesh ensures that the structures can withstand various stresses, including vibrations, shocks, and weight loads.

In addition to typical construction scenarios, Reo mesh is also utilized in specialized applications. For instance, in road and bridge construction, the mesh provides essential support to pavements and deck slabs, significantly enhancing their load-bearing capacities and resistance to cracking.

Furthermore, Reo mesh is critical in the creation of precast concrete products such as pipes, walls, and blocks. These products must endure high stress during transportation and installation, making the reinforcement provided by Reo mesh essential. Additionally, its use in retaining walls and embankments helps prevent soil erosion and landslides, contributing to environmental safety.

The Future of Reo Mesh Manufacturing

As the demand for sustainable and efficient building materials grows, the Reo mesh manufacturing industry is poised for significant growth. Manufacturers are increasingly adopting eco-friendly practices, such as sourcing recycled steel and utilizing energy-efficient manufacturing processes. This shift not only reduces the environmental impact but also caters to the growing market of environmentally-conscious construction projects.

Moreover, the integration of advanced technologies such as 3D printing and smart manufacturing could revolutionize the production of Reo mesh, allowing for even greater customization and efficiency. As engineers and architects continue to design more complex structures, the adaptability of Reo mesh will be crucial in meeting these evolving demands.

Conclusion

Reo mesh manufacturers play a vital role in the construction industry by providing essential products that ensure the structural integrity and safety of buildings and infrastructures. With ongoing innovations and a focus on sustainability, the future of Reo mesh looks promising. As we continue to build complex and sustainable environments, the importance of reliable reinforcement will only increase, solidifying Reo mesh’s role as a cornerstone of modern construction.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025