Dec . 04, 2024 10:15 Back to list

reo mesh factory

The Significance of Reo Mesh Factory in Modern Construction

In the realm of modern construction, the materials used can significantly influence the strength, durability, and overall success of a project. Among these essential materials, Reinforced Steel Mesh (Reo mesh) has emerged as a staple component, especially in concrete applications. As construction techniques evolve and the demand for robust structures increases, Reo mesh factories play a pivotal role in ensuring quality production and supply of this critical resource.

What is Reo Mesh?

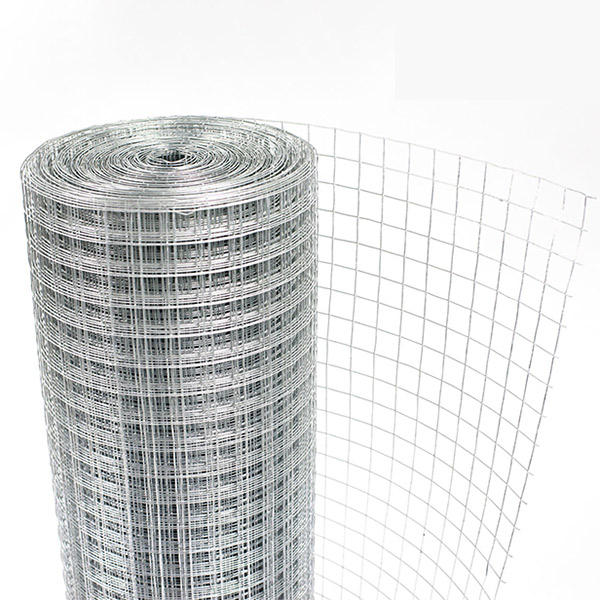

Reo mesh, short for reinforced steel mesh, consists of a network of steel wires that are welded or woven together to create a grid-like pattern. This mesh is primarily utilized in concrete reinforcement, serving to enhance the tensile strength of concrete, which is naturally weak in tension. By incorporating Reo mesh into concrete slabs, walls, and other structural elements, engineers can create safer and more resilient edifices capable of withstanding various stresses, including those from environmental factors, heavy loads, and seismic activity.

The Manufacturing Process of Reo Mesh

The production of Reo mesh involves several critical steps, each contributing to the final product's integrity and effectiveness. First, high-quality steel is sourced, often from recycled materials, ensuring sustainability and reducing the carbon footprint. The steel rods are then cut to the required lengths and arranged in compliance with specific engineering designs.

Once the arrangement is set, the welding process begins. Automated welding machines ensure precision and uniformity, critical factors for ensuring that the mesh can perform its intended function uniformly throughout the structure. The final products undergo rigorous quality control measures, including tensile testing and load testing, to ensure they meet industry standards and can withstand the stresses they will face in service.

Applications and Benefits of Reo Mesh

reo mesh factory

Reo mesh is widely used in various construction applications, including residential buildings, commercial structures, bridges, and industrial facilities. Its benefits are multifold, primarily revolving around structural integrity. Here are some key advantages

1. Enhanced Strength Reo mesh significantly increases the tensile strength of concrete, allowing structures to bear more weight and resist cracking under stress. 2. Cost-Effective While the initial investment in Reo mesh may be higher than traditional reinforcement methods, it often leads to long-term savings due to reduced maintenance and repair costs. 3. Versatility Reo mesh can be custom-designed to meet specific project requirements, making it suitable for a wide range of construction types and applications. 4. Ease of Installation The mesh can be easily positioned on-site, allowing for faster setup times and reducing labor costs during the construction phase.

Sustainability Concerns

As with many industries today, sustainability is a critical consideration for Reo mesh factories. Many manufacturers are taking significant steps to ensure their operations are environmentally friendly. This includes using recycled steel, optimizing production processes to reduce waste, and implementing energy-efficient technologies in their manufacturing plants. By embracing sustainable practices, these factories not only contribute to the longevity of their products but also play a role in reducing the overall environmental impact of the construction industry.

Future Trends in Reo Mesh Production

Looking ahead, the Reo mesh industry is poised for growth due to advancements in technology and increased demand for high-performance construction materials. Innovations such as automated manufacturing processes, the use of alternative materials such as fiber-reinforced composites, and enhanced coating techniques to improve corrosion resistance are emerging trends. Such developments promise to further elevate the performance characteristics of Reo mesh, making it an even more attractive choice for construction professionals.

Conclusion

The Reo mesh factory is an integral piece of the modern construction puzzle, providing essential components that enhance the safety and longevity of structures worldwide. As demands for stronger, more sustainable buildings continue to rise, the role of Reo mesh and its production facilities becomes ever more crucial. By focusing on quality manufacturing, sustainability, and innovation, the Reo mesh industry is set to contribute significantly to the future of construction, paving the way for durable, resilient, and eco-friendly buildings.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025