Aug . 07, 2024 15:40 Back to list

Reliable Suppliers for Galvanized Wire Brick Force Mesh for Construction and Industrial Applications

Understanding Galvanized Wire Brick Force Mesh An Essential in Construction

In the realm of construction and structural engineering, the materials used play a crucial role in determining the strength and longevity of a building. Among these materials, galvanized wire brick force mesh has gained significant attention for its exceptional properties and diverse applications. This article will explore what galvanized wire brick force mesh is, its benefits, and why selecting reputable suppliers is essential for construction projects.

What is Galvanized Wire Brick Force Mesh?

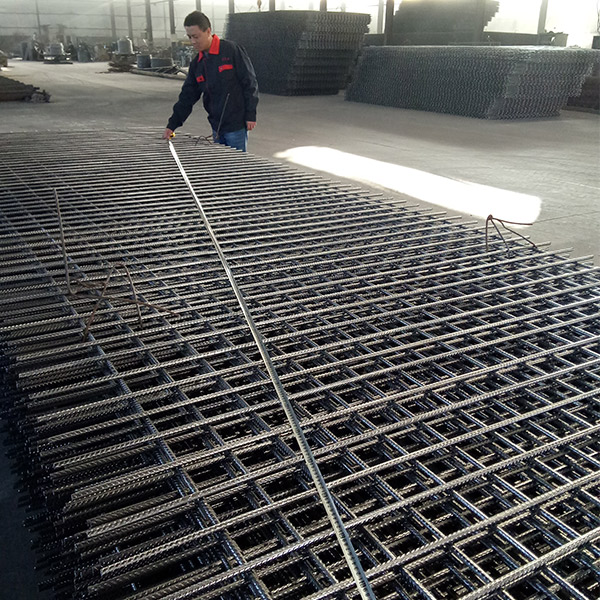

Galvanized wire brick force mesh is a type of reinforcement mesh made from galvanized steel wire. The galvanization process involves coating steel wire with a thin layer of zinc to prevent corrosion, ensuring durability and longevity. This mesh is typically composed of welded wire grids that are designed to provide added strength to structures that involve brickwork or masonry. It is commonly used between layers of bricks or blocks to enhance structural integrity, especially in load-bearing walls.

Benefits of Using Galvanized Wire Brick Force Mesh

1. Corrosion Resistance One of the primary advantages of galvanized wire is its resistance to rust and corrosion. This attribute makes galvanized wire brick force mesh particularly suitable for outdoor constructions or environments with high humidity and moisture levels, where traditional steel would deteriorate over time.

2. Increased Strength The welded structure of the mesh distributes loads evenly, providing enhanced stability to walls or other masonry units. This quality is vital for buildings that need to withstand various stresses, including seismic activity or heavy loads.

3. Ease of Installation Galvanized wire brick force mesh is relatively easy to handle and install. Its lightweight nature simplifies transportation and allows for quicker installation compared to heavier reinforcing materials. The mesh can easily be cut to size, fitting the specific dimensions necessary for different projects.

5. Eco-Friendly Option Galvanized steel is recyclable, contributing to more sustainable construction practices. By using this material, builders can participate in environmentally friendly construction efforts.

galvanized wire brick force mesh suppliers

Choosing Reliable Suppliers

The effectiveness of galvanized wire brick force mesh largely depends on the quality of the product being used. It is imperative for contractors and builders to choose reliable suppliers who provide high-quality materials that meet industry standards. Here are several tips for selecting the right supplier

1. Reputation and Reviews Research suppliers online, and check for reviews and testimonials from previous clients. A supplier with a reputable track record is more likely to deliver quality products.

2. Quality Assurance Ensure that the supplier follows strict quality control measures during manufacturing. Look for certifications that vouch for the quality and safety of their products.

3. Diverse Product Range A good supplier should offer various types of mesh and wire products, allowing for flexibility in material selection based on project demands.

4. Customer Support Strong customer service is essential. Suppliers who provide good support and advice can help contractors make informed decisions about the products that best suit their needs.

5. Competitive Pricing While quality is paramount, it is wise to compare prices among suppliers to ensure that you are getting the best value for money without compromising on quality.

Conclusion

Galvanized wire brick force mesh is a vital component in modern construction, providing increased strength and corrosion resistance that is essential for structural integrity. With numerous suppliers in the market, choosing a reputable one ensures access to high-quality materials, ultimately contributing to the success of construction projects. By prioritizing quality and service, builders can achieve durability and longevity in their constructions, making galvanized wire brick force mesh an indispensable choice in today’s construction industry.

-

Glass Jar with Wooden Screw Lid-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Thermal Resistance&Eco-Friendly

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|High Borosilicate Glass&Eco-Friendly Design

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Thermal Resistance Eco-Friendly Airtight Seal

NewsAug.17,2025

-

Glass Jar with Wooden Screw Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.17,2025

-

Diamond Steel Grating Factory: Leading Manufacturer & Supplier

NewsAug.17,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Premium Eco-Friendly Storage Solution|Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsAug.16,2025