Nov . 27, 2024 11:34 Back to list

Manufacturers of A193 Reinforcing Wire Mesh for Construction Applications

Understanding Reinforcing Wire Mesh A193 Manufacturers and Their Role

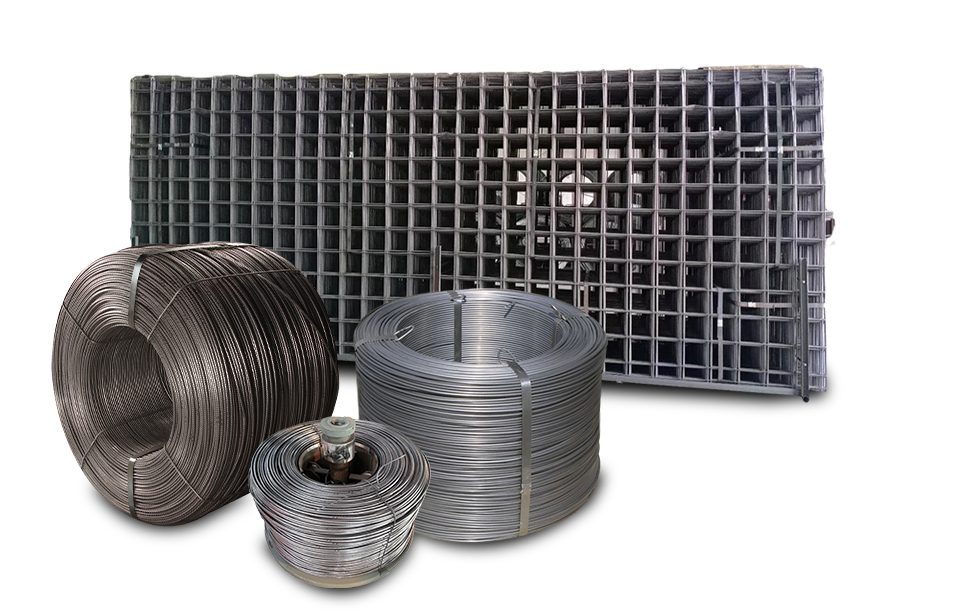

Reinforcing wire mesh is a critical component in the construction industry, used for enhancing the tensile strength of concrete structures. Among the various standards and specifications, A193 is a notable specification that deals with reinforcement needs. This article explores the significance of A193 reinforcing wire mesh, the manufacturing process, and the key manufacturers in the field.

The Importance of Reinforcing Wire Mesh

Reinforcing wire mesh serves as a framework within concrete, which helps to prevent cracking and structural failure. Its primary function is to distribute loads, providing a robust support system that enhances the durability of concrete slabs, walls, and other structures. Using wire mesh is especially critical in areas that experience high stress or require increased load capacity.

The A193 specification, set by ASTM International, outlines the requirements for alloy-steel and stainless-steel bolting materials for high-temperature or high-pressure service and other special applications. Although it primarily focuses on bolting, its principles and quality considerations extend to reinforcing wire mesh, ensuring that manufacturers meet strict quality controls and standards for heavy-duty applications.

Manufacturing Process

The manufacturing of reinforcing wire mesh involves several stages, starting from the selection of raw materials to the final production of mesh sheets. Here’s a concise overview of the process

1. Material Selection High-quality steel is chosen for its strength and durability. The specific type of steel can vary based on the requirements of the project, but it typically adheres to the A193 standards for mechanical properties.

2. Wire Drawing The selected steel is drawn through a series of dies to produce wires of desired diameters. This process enhances the tensile strength of the wire.

3. Mesh Fabrication The drawn wires are then woven or welded together to create sheets of reinforcing wire mesh. The configuration and spacing of the wires are tailored based on project specifications, ensuring adequate support.

reinforcing wire mesh a193 manufacturers

4. Quality Control Quality checks are performed at various stages of production to ensure that the wire mesh meets A193 specifications. This includes tests for strength, corrosion resistance, and overall durability.

5. Finishing After quality assurance, the reinforcing meshes may undergo treatments like galvanization to enhance their resistance to rust and environmental wear, prolonging their lifespan.

Key Manufacturers

Several manufacturers specialize in producing A193-reinforcing wire mesh, each with unique offerings and strengths. Here are some notable players in the field

1. XYZ Steel Supplies Renowned for its commitment to quality, XYZ Steel Supplies adheres strictly to A193 specifications, ensuring that their products are suitable for aviation and aerospace applications. Their advanced manufacturing techniques allow for tailored solutions to specific project requirements.

2. ABC Mesh Co. With a range of wire mesh sizes and configurations, ABC Mesh Co. has established itself as a leader in construction materials. Their robust production processes and rigorous quality controls make them a top choice for contractors across various industries.

3. Steel Mesh Innovations Focusing on innovation, Steel Mesh Innovations offers specially engineered wire mesh systems that can withstand extreme conditions. Their products are backed by extensive research and development, ensuring they meet and exceed A193 standards.

4. Global Wire Solutions This company is known for its eco-friendly production practices and a wide array of metal mesh products. Their commitment to sustainability and quality has made them a popular choice among environmentally conscious contractors.

Conclusion

Reinforcing wire mesh A193 is a crucial element in modern construction, providing essential support and strength to concrete structures. Understanding the manufacturing process and the key players in the industry helps builders and contractors to make informed decisions when selecting materials. By prioritizing quality and compliance with specifications such as A193, manufacturers ensure that the end products meet the demanding needs of the construction sector. As projects continue to evolve and requirements become more stringent, the role of reliable reinforcing wire mesh manufacturers will be ever more significant in ensuring the integrity and longevity of our infrastructure.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025