Nov . 09, 2024 15:33 Back to list

A193 Factory for High-Quality Reinforcing Wire Mesh Production

The Importance of Reinforcing Wire Mesh A193 in Construction

Reinforcing wire mesh, particularly the A193 grade, plays a crucial role in modern construction, offering strength, durability, and cost-effectiveness. This specialized mesh is designed to provide structural reinforcement in concrete applications, ensuring the longevity and safety of structures. In this article, we will explore the significance of reinforcing wire mesh A193, its manufacturing process, applications, and the benefits it brings to construction projects.

What is Reinforcing Wire Mesh A193?

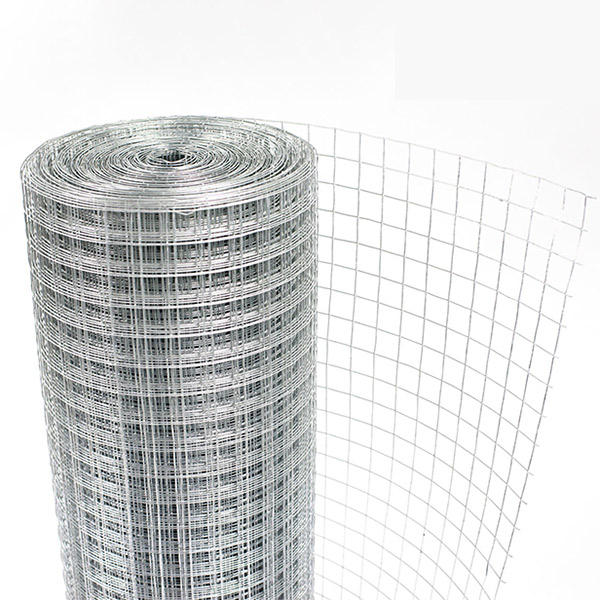

Reinforcing wire mesh A193 is made from high-quality steel wires that are welded together to form a grid-like structure. The mesh is specifically crafted to enhance the tensile strength of concrete, enabling it to withstand various stresses and loads. A193 refers to a specific grade of wire mesh that meets the standards laid out by the American Society for Testing and Materials (ASTM), ensuring that it possesses the necessary mechanical properties for effective reinforcement.

Manufacturing Process

The manufacturing process of A193 reinforcing wire mesh begins with the selection of high-grade steel wire, which is drawn to the required diameters. These wires are then pre-stretched and cleaned to remove any contaminants that could affect their performance. Following this, the wires are arranged in a grid-like pattern and welded together at the intersections. This welding process is critical as it ensures the integrity and strength of the mesh.

After welding, the mesh undergoes treatment to enhance its corrosion resistance, often through galvanization or the application of protective coatings. This step is essential for ensuring that the wire mesh can withstand harsh environmental conditions, which could otherwise lead to deterioration over time.

Applications in Construction

Reinforcing wire mesh A193 is versatile and is widely used in various construction applications. Some of its primary uses include

1. Concrete Slabs It is commonly used in flooring, driveways, and pavements to help distribute loads evenly, minimizing the risk of cracking.

reinforcing wire mesh a193 factory

3. Precast Concrete Elements A193 mesh is often utilized in precast concrete products, such as beams, columns, and panels, contributing to their overall strength and stability.

4. Bridges and Overpasses In larger infrastructure projects, reinforcing wire mesh plays a vital role in enhancing the load-bearing capacity of bridges and overpasses.

Benefits of Using A193 Wire Mesh

The advantages of using A193 reinforcing wire mesh in construction are numerous

- Enhanced Structural Integrity The primary benefit is improved structural integrity. By distributing loads evenly, A193 mesh helps prevent cracks and failures, extending the lifespan of concrete structures.

- Cost-Effectiveness Utilizing wire mesh can reduce the amount of concrete needed and minimize repair costs associated with cracking and structural deterioration.

- Versatility A193 mesh is adaptable to various construction applications, making it a go-to choice for many engineers and builders.

- Ease of Installation The grid layout of the mesh simplifies installation, allowing for quicker project completion while ensuring high-quality reinforcement.

Conclusion

Reinforcing wire mesh A193 is an essential component in the field of construction, providing critical support to concrete structures. With its ability to enhance strength, promote durability, and reduce costs, it is no wonder that this product has become a standard in the industry. As construction technology continues to evolve, the reliance on quality materials like A193 will undoubtedly grow, helping to shape safer and more resilient built environments for the future. Whether you're a contractor, engineer, or architect, understanding the value of reinforcing wire mesh A193 can lead to more successful and sustainable construction projects.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025