Nov . 26, 2024 04:03 Back to list

Top Manufacturers of Reinforcing Mesh Panels for Construction Industry

Understanding Reinforcing Mesh Panels and Their Manufacturers

In the construction industry, the use of reinforcing mesh panels has become increasingly important for ensuring the integrity and durability of structures. These panels, typically made of steel, play a crucial role in reinforcing concrete, providing the strength needed to withstand the pressures and stresses of various applications. To understand their significance, it’s essential to delve into what reinforcing mesh panels are, their benefits, and the role of manufacturers in producing high-quality products.

What Are Reinforcing Mesh Panels?

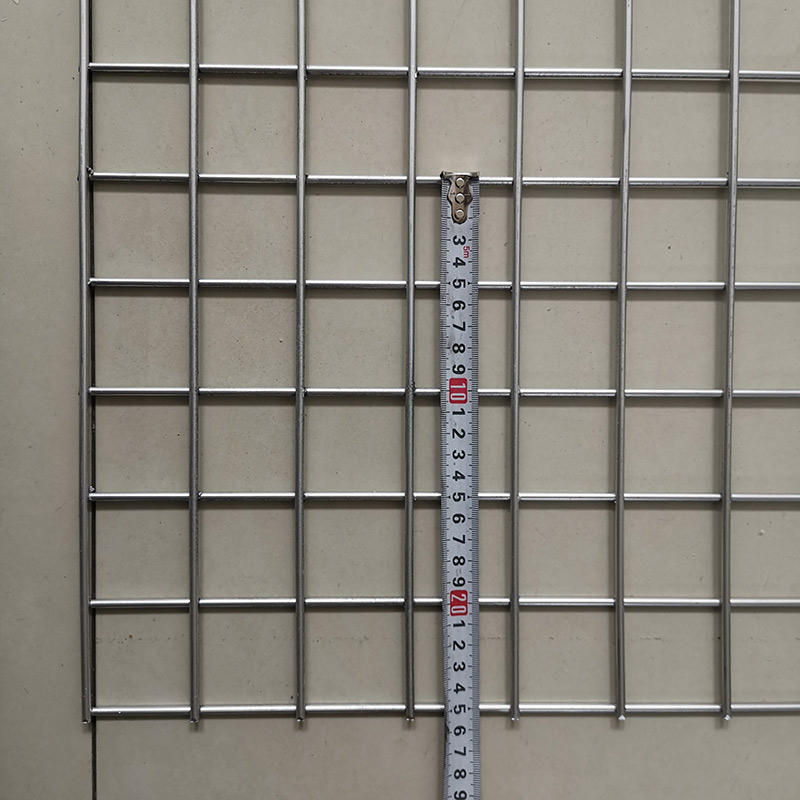

Reinforcing mesh panels are grids made from steel wire, carefully arranged to create a network that enhances the tensile strength of concrete. They are used in various construction projects, including residential buildings, highways, bridges, and industrial facilities. The panels are available in different sizes and wire diameters, allowing them to cater to specific structural requirements.

The manufacturing process involves welding or weaving steel wires together to create a stable mesh that meets industry standards. Once produced, these panels can be cut and shaped to fit specific dimensions required for different construction projects. Their primary purpose is to distribute loads evenly across a concrete structure, preventing cracks and structural failure over time.

Benefits of Using Reinforcing Mesh Panels

1. Enhanced Strength Reinforcing mesh panels significantly increase the compressive and tensile strength of concrete. This added strength is essential for heavy load-bearing constructions, ensuring that buildings can withstand both static and dynamic loads.

2. Crack Prevention One of the most significant benefits of incorporating mesh panels is their ability to minimize crack formation. By maintaining the integrity of the concrete and controlling shrinkage, these panels help prolong the lifespan of structures.

3. Efficiency in Construction Using reinforcing mesh panels streamlines the construction process. Their pre-manufactured sizes and easy installation procedures reduce the time and labor costs associated with reinforcing concrete, allowing projects to move forward more quickly.

4. Versatility These panels can be utilized in a variety of applications, from floor slabs to walls and even precast elements. Their adaptability makes them a preferred choice among builders and architects.

reinforcing mesh panels manufacturers

5. Cost-Effectiveness Investing in quality reinforcing mesh panels can lead to cost savings in the long run. While there may be initial costs associated with purchasing these panels, the prevention of structural issues and the reduced need for repairs make them a financially sound choice.

Role of Manufacturers

The manufacturing of reinforcing mesh panels is a specialized field that involves rigorous quality control and adherence to industry standards. Manufacturers play a pivotal role in ensuring that the materials used meet specific criteria for strength and durability.

1. Quality Assurance Reputable manufacturers conduct extensive testing on their materials to ensure they withstand various environmental conditions and loads. Consistency in quality is vital for maintaining the structural integrity of constructions, and manufacturers must adhere to international and local standards.

2. Customization Many manufacturers offer customization options for reinforcing mesh panels. This flexibility allows them to cater to the unique requirements of different projects. Whether it’s adjusting the size, wire gauge, or spacing, manufacturers can design panels that meet clients’ specifications.

3. Research and Development Leading manufacturers invest in research and development to innovate new products and techniques for reinforcing mesh panels. By exploring advanced materials and technologies, they contribute to safer and more efficient construction practices.

4. Sustainability Practices As concerns about environmental impact grow, many manufacturers are adopting sustainable practices in their production processes. This includes using recycled materials and minimizing waste, thus contributing to greener construction solutions.

5. Reliability and Support A trustworthy manufacturer not only provides quality products but also offers additional support services. This includes technical assistance, installation guidance, and prompt delivery services, ensuring that contractors have everything they need for their projects.

Conclusion

Reinforcing mesh panels are essential components in modern construction, providing strength, durability, and longevity to concrete structures. The role of manufacturers in producing high-quality, reliable mesh panels cannot be overstated. As the industry continues to evolve, the importance of these panels and the manufacturers behind them will only grow, leading to safer and more sustainable building practices worldwide. Embracing innovation and quality, the future of reinforcing mesh panels is bright, promising enhanced building resilience for generations.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025