Oct . 31, 2024 14:18 Back to list

High-Quality Reinforcing Mesh Production for Strong and Durable Construction Solutions

Understanding Reinforcing Mesh Manufacturers Importance and Applications

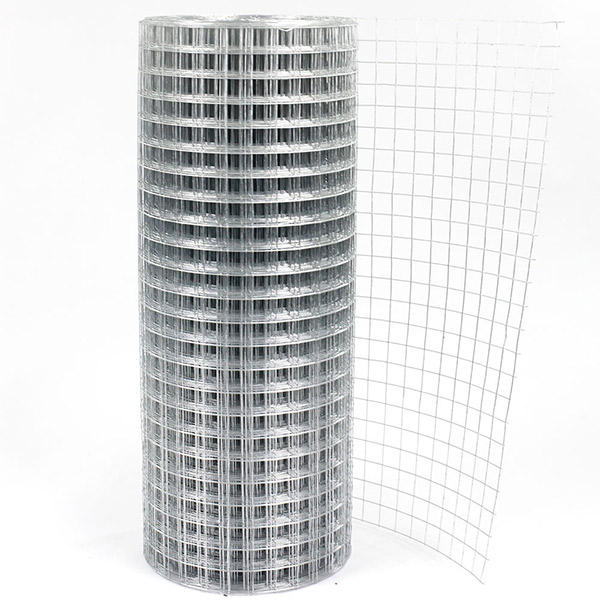

Reinforcing mesh, commonly known as welded wire mesh, plays a pivotal role in the construction industry. It is primarily used to provide tensile strength to concrete structures, ensuring they can withstand various stresses and loads. The demand for high-quality reinforcing mesh has led to the emergence of numerous manufacturers focusing on producing this essential product.

What is Reinforcing Mesh?

Reinforcing mesh is made from steel wire that is welded together to form a grid. This grid is then used to reinforce concrete in various applications, such as floors, walls, and slabs. By integrating reinforcing mesh into concrete, builders can enhance the material's structural integrity, extend its lifespan, and reduce the risk of cracks and failures.

The Role of Manufacturers

Manufacturers of reinforcing mesh are crucial to ensuring that the construction industry has access to reliable and durable products. They focus on several key aspects

1. Quality Control High-quality reinforcing mesh is essential for safety and longevity in construction. Manufacturers implement strict quality control processes to ensure their products meet industry standards and specifications. This involves using premium-grade steel and employing advanced manufacturing techniques.

2. Customization Different construction projects require different types of reinforcing mesh. Reputable manufacturers offer customization options, allowing builders to specify the size, shape, and type of mesh needed for their specific applications. This flexibility enables manufacturers to cater to a diverse range of projects, from residential buildings to large commercial infrastructures.

reinforcing mesh manufacturer

3. Sustainability With the growing emphasis on sustainable practices in the construction industry, many manufacturers are adopting eco-friendly techniques. This includes using recyclable materials and minimizing waste during production. By focusing on sustainability, manufacturers are not only meeting regulations but also appealing to environmentally conscious clients.

4. Research and Development The construction landscape is constantly evolving, and reinforcing mesh manufacturers are at the forefront of innovation. They invest in research and development to produce advanced mesh products that enhance performance. This may involve the use of new materials or technologies that improve tensile strength, corrosion resistance, and overall durability.

Applications of Reinforcing Mesh

The applications of reinforcing mesh are widespread and varied. It is commonly used in

- Residential Construction From foundations to walls and floors, reinforcing mesh is integral in ensuring the structural safety of homes. - Commercial Buildings Larger commercial projects, such as shopping malls and office buildings, require durable solutions to withstand higher loads and traffic. - Infrastructure Projects Roads, bridges, and dams utilize reinforcing mesh to enhance their structural integrity, ensuring they can handle environmental stresses over time.

Conclusion

In conclusion, reinforcing mesh manufacturers play an essential role in the construction industry by providing high-quality products that enhance the safety and durability of concrete structures. Their commitment to quality, customization, sustainability, and innovation ensures that builders have the resources they need to complete projects successfully. As construction practices continue to evolve, so too will the capabilities of reinforcing mesh manufacturers, making them indispensable partners in building the future.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025