Nov . 08, 2024 19:25 Back to list

reinforcing mesh for industrial manufacturers

Reinforcing Mesh for Industrial Manufacturers A Comprehensive Overview

In the fast-evolving world of construction and manufacturing, the importance of robust and reliable materials cannot be overstated. Among these, reinforcing mesh plays a crucial role in providing structural integrity and stability across a variety of applications. This article delves into the significance of reinforcing mesh for industrial manufacturers, exploring its composition, applications, advantages, and future trends.

What is Reinforcing Mesh?

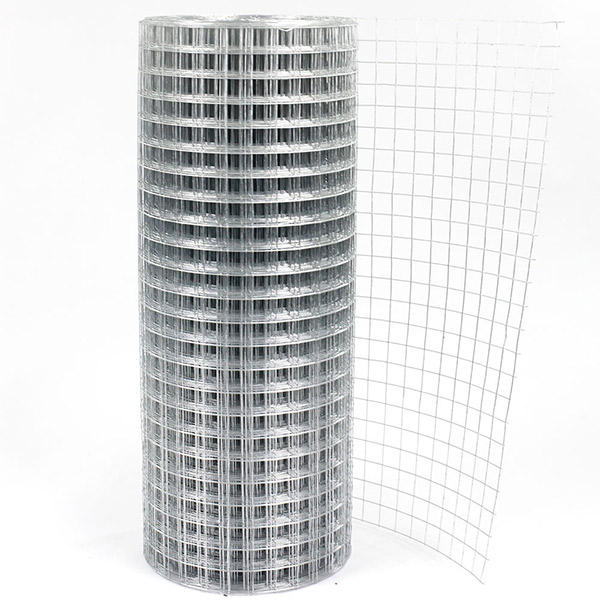

Reinforcing mesh, often referred to as welded wire mesh or rebar mesh, is a grid-like structure made from steel wires that are welded together at regular intervals. This mesh is primarily used in concrete applications to enhance tensile strength and prevent cracking, thereby increasing the longevity and durability of structures. The design typically involves a series of longitudinal and transverse wires, arranged in a square or rectangular pattern, which provides even distribution of stress across the surface.

Applications Across Industries

The versatility of reinforcing mesh makes it indispensable in various industries. Its primary application remains in construction, where it is utilized for

1. Concrete Slabs In commercial and residential buildings, reinforcing mesh is embedded in concrete slabs to provide stability and prevent cracking due to temperature changes and heavy loads. 2. Road and Pavement Construction Mesh is used in highway and pavement construction to improve load-carrying capacity and reduce maintenance costs over time.

3. Precast Concrete Products Industrial manufacturers often incorporate reinforcing mesh in precast products such as walls, beams, and flooring systems, ensuring consistent quality and performance.

4. Retaining Walls For earth retention solutions, reinforcing mesh provides the necessary support to withstand lateral forces exerted by soil and water.

Advantages of Reinforcing Mesh

The use of reinforcing mesh offers numerous advantages that appeal to industrial manufacturers

1. Enhanced Strength By improving the tensile strength of concrete, reinforcing mesh allows for the construction of safer and more durable structures.

reinforcing mesh for industrial manufacturers

2. Cost-Effectiveness While the initial investment in quality reinforcing mesh may be higher than traditional reinforcements, its long-term benefits include reduced maintenance and repair costs associated with structural failures.

3. Ease of Installation The mesh can be easily cut and shaped to meet specific design requirements, streamlining the construction process. Its lightweight nature also allows for easier handling.

4. Versatility Reinforcing mesh can be used in various construction methods—whether it is cast-in-place, precast, or shotcrete applications—making it suitable for a wide range of projects.

Future Trends and Innovations

As the construction industry faces challenges such as rising material costs and sustainability concerns, the future of reinforcing mesh is likely to be shaped by innovation and technology. Some trends to watch for include

1. Sustainable Materials With increasing emphasis on eco-friendly construction practices, manufacturers are exploring alternatives to traditional steel. Innovations in synthetic meshes or recycled materials promise to reduce the environmental footprint of reinforcing mesh.

2. Advanced Coatings Corrosion-resistant coatings are being developed to extend the life of reinforcing mesh, particularly in harsh environments where exposure to moisture and chemicals is prevalent.

3. Smart Reinforcing Mesh The integration of technology may lead to the development of smart reinforcing solutions that can monitor structural health in real time, providing critical data on stress and potential failure points.

4. Customization and Automation Advances in technology are likely to introduce automated production techniques and customization options that allow manufacturers to design mesh solutions tailored to specific project requirements.

Conclusion

In summary, reinforcing mesh serves as a foundational component in the construction and manufacturing sectors, providing essential support and durability to concrete structures. As industrial manufacturers continue to innovate and adapt to emerging challenges, reinforcing mesh will play a pivotal role in ensuring the safety and longevity of our built environment. With ongoing advancements in materials and technology, the future looks promising for this critical element of construction.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025