Dec . 01, 2024 17:35 Back to list

reinforcing mesh for industrial factory

The Importance of Reinforcing Mesh in Industrial Factories

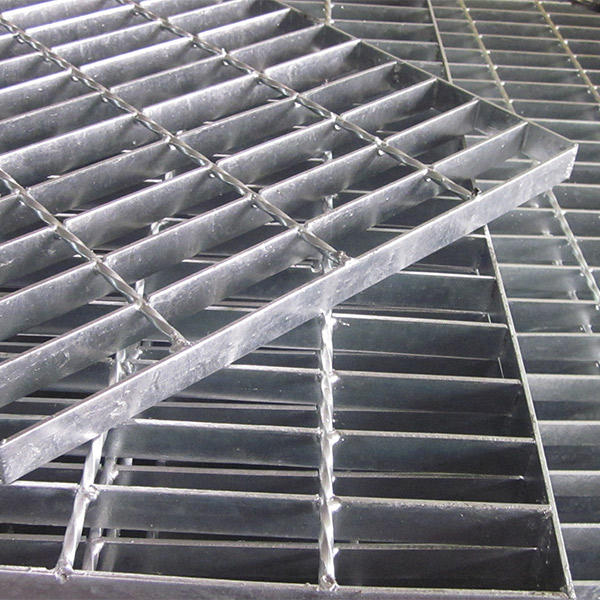

In the realm of construction and industrial manufacturing, the integrity and durability of structures are paramount. One of the critical components that contribute significantly to this integrity is reinforcing mesh. Reinforcing mesh, often referred to as welded wire mesh, plays an essential role in enhancing the strength and robustness of concrete structures, particularly in industrial factory settings.

Understanding Reinforcing Mesh

Reinforcing mesh consists of a grid of steel wires that are welded together at intersections to form a stable framework. This mesh is embedded within concrete slabs, walls, and other structural components, providing support that resists tension and prevents cracking. The use of reinforcing mesh in industrial factories is particularly beneficial due to the heavy loads and stresses that these structures are subjected to.

The primary purpose of reinforcing mesh is to distribute loads evenly across the concrete surface. In industrial environments, equipment, machinery, and storage facilities often require foundations and floors that can withstand significant weight. Reinforcing mesh ensures that the concrete maintains its structural integrity under such demanding conditions, significantly reducing the risk of failure.

Advantages of Using Reinforcing Mesh

1. Enhanced Strength and Durability One of the primary benefits of using reinforcing mesh in industrial applications is its ability to enhance the compressive and tensile strength of concrete. It helps prevent cracking and deformation, which can be caused by heavy machinery and equipment vibrations.

2. Cost-Effectiveness While the initial installation of reinforcing mesh might represent an added expense, it is a cost-effective investment in the long run. By minimizing the risk of structural failures or the need for extensive repairs, reinforcing mesh can save significant costs associated with downtime and maintenance in an industrial setting.

reinforcing mesh for industrial factory

3. Ease of Installation Reinforcing mesh is relatively easy to install and can be customized to fit various project requirements. This adaptability makes it a preferred choice for many industrial construction projects, where specific dimensions and configurations may be required.

4. Improved Safety In factory environments, workplace safety is a critical concern. Using reinforcing mesh reduces the chances of accidents due to structural failures, providing peace of mind for both workers and management. Well-constructed floors and walls contribute to a safer work environment.

5. Sustainability In the current climate, sustainability is a growing concern. Reinforcing mesh can contribute to greener construction practices. Steel used in reinforcing mesh is often recyclable, reducing the environmental impact of construction and renovation projects.

Applications in Industrial Factories

The applications of reinforcing mesh in industrial factories are extensive. It is commonly used in the construction of factory floors, where heavy machinery operates daily. Additionally, it is utilized in walls and slabs of loading docks, storage areas, and production lines. The versatility of reinforcing mesh allows it to be adapted to various construction scenarios, ensuring that every aspect of the factory is fortified against potential structural issues.

Conclusion

In conclusion, reinforcing mesh is a crucial element in the construction and maintenance of industrial factories. Its ability to enhance strength, durability, and safety makes it an indispensable material in industrial applications. Given the demanding environments these factories operate in, investing in reinforcing mesh is not merely a choice but a necessity for ensuring long-term structural integrity and minimizing operational risks. As industrial practices continue to evolve, the role of reinforcing mesh will remain vital in supporting the infrastructure needed for efficient and safe manufacturing processes.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025