Nov . 19, 2024 08:55 Back to list

Supplier of Reinforcement Mesh for Concrete Slabs and Construction Projects

Reinforcing Mesh for Concrete Slab A Comprehensive Guide for Suppliers

Concrete slabs are a vital component in the construction industry, serving as the foundation for structures ranging from residential homes to skyscrapers. To ensure the durability and strength of these slabs, reinforcing mesh has become an essential material. As a supplier of reinforcing mesh for concrete slabs, it is important to understand its significance, types, applications, and how to choose the right product for your needs.

Understanding Reinforcing Mesh

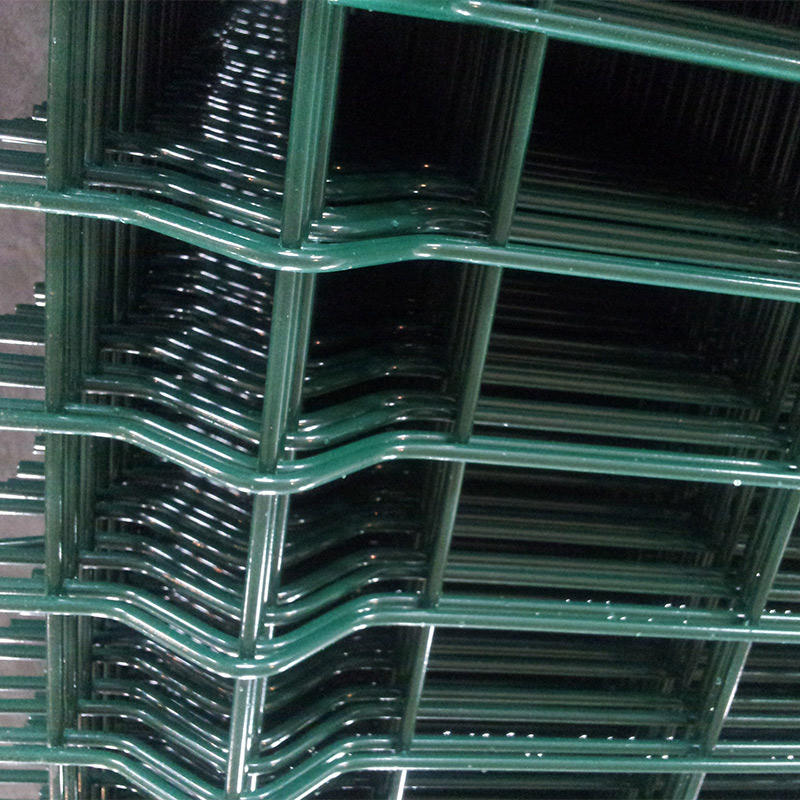

Reinforcing mesh, also known as welded wire mesh or rebar mesh, is a type of steel reinforcement used in concrete construction. It comprises a grid of wires that are welded together at intersections, providing strength and stability to the concrete slab. The primary purpose of reinforcing mesh is to help withstand tensile forces that concrete alone cannot resist. By incorporating this material, the overall structural integrity of the slab is significantly enhanced, reducing the risk of cracking and other failures.

Types of Reinforcing Mesh

There are various types of reinforcing mesh available in the market, each designed for specific applications

1. Welded Wire Mesh This is the most common type used in concrete slabs. It consists of cold-drawn wires that are welded together at regular intervals. It is easy to handle and can be produced in different sizes and gauges.

2. Rebar Mesh Made from rebar, this type of mesh provides heavy-duty reinforcement for larger slabs subject to high loads. It can be custom fabricated to meet specific project requirements.

3. Fiber-Reinforced Mesh This mesh incorporates synthetic or natural fibers, enhancing the concrete’s crack resistance and toughness, especially in slabs that are subject to shrinkage.

4. Galvanized Mesh This type is coated with a layer of zinc to prevent corrosion, making it suitable for use in environments where concrete may be exposed to moisture or chemicals.

Applications of Reinforcing Mesh

The applications of reinforcing mesh are diverse and widespread

reinforcing mesh for concrete slab supplier

- Floor Slabs In residential and commercial buildings, reinforcing mesh is commonly used in floor slabs to support heavy loads and provide a flat surface.

- Pavements Reinforcing mesh is vital in road construction, ensuring durability and reducing the risk of cracking under traffic loads.

- Foundations In foundation work, it is used to reinforce concrete to prevent settling and shifting.

- Structural Elements Beyond slabs, reinforcing mesh can also be used in columns, beams, and walls to enhance overall structural performance.

Choosing the Right Reinforcing Mesh

Selecting the appropriate reinforcing mesh for a concrete slab project involves considering various factors

1. Load Requirements Evaluate the anticipated loads on the slab. For heavier loads, thicker and stronger mesh is necessary.

2. Environmental Conditions Consider the environment where the slab will be located. For areas prone to moisture, corrosion-resistant mesh is advisable.

3. Thickness of the Slab The thickness of the concrete slab will influence the type and size of the mesh. Thicker slabs may require heavier gauge mesh.

4. Local Regulations Always check local building codes and regulations that may dictate specific requirements for reinforcing materials.

Conclusion

As a supplier of reinforcing mesh for concrete slabs, understanding the importance of this material is crucial for providing high-quality products that meet the needs of your customers. By offering a variety of reinforcing mesh types and educating clients on their applications, you can help ensure the success of their construction projects. With the right reinforcement, concrete slabs not only become stronger and more durable but also contribute to the longevity and safety of buildings. Investing in quality reinforcing mesh is an investment in the future strength of infrastructure.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025