Nov . 11, 2024 22:27 Back to list

reinforcing mesh for concrete slab manufacturers

Reinforcing Mesh for Concrete Slab Manufacturers A Crucial Component in Modern Construction

In the modern construction industry, reinforcing mesh plays a pivotal role in ensuring the structural integrity and durability of concrete slabs. It is particularly essential for manufacturers who specialize in producing high-quality concrete elements that meet various engineering standards and client expectations. This article explores the significance of reinforcing mesh, its applications in concrete slabs, and the considerations manufacturers must keep in mind when working with this vital material.

Understanding Reinforcing Mesh

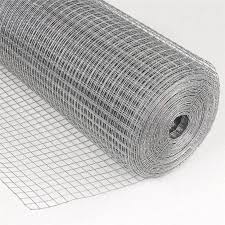

Reinforcing mesh, often referred to as welded wire mesh, is a grid of steel wires that are welded together at regular intervals. This mesh is embedded within concrete to enhance its tensile strength, which is crucial since concrete, while strong under compression, can be quite weak under tension. The addition of reinforcing mesh helps to mitigate the risk of cracking and increases the lifespan of the concrete slab.

Manufacturers of reinforcing mesh utilize high-quality steel that adheres to industry standards, ensuring that the final product can withstand the demands of various construction projects. The type of mesh used can vary depending on the intended application, with options such as plain wire mesh, galvanized mesh for corrosion resistance, and high-tensile options that provide even greater strength.

Applications in Concrete Slabs

Reinforcing mesh is widely used in constructing various types of concrete slabs, including

1. Residential Slabs Reinforcement is crucial in slab-on-grade foundations that support homes. The mesh helps prevent cracking caused by soil movement and temperature changes.

2. Commercial Floors In commercial construction, heavy loads and high foot traffic require durable floors. The use of reinforcing mesh ensures that these slabs can handle the stress without compromising integrity.

3. Industrial Applications Factories and warehouses often necessitate robust flooring that can accommodate machinery and heavy equipment. Reinforcing mesh enhances the structural performance of these slabs.

4. Infrastructure Projects Bridges, roads, and airport runways rely on reinforced concrete to endure varied environmental conditions and heavy loads.

reinforcing mesh for concrete slab manufacturers

Considerations for Manufacturers

For manufacturers specializing in reinforcing mesh production for concrete slabs, several factors must be considered to ensure product quality and functionality

1. Material Selection The choice of steel quality is fundamental. Manufacturers must use materials that meet or exceed local and international standards, ensuring that the mesh can withstand harsh conditions and resist corrosion.

2. Welding Techniques The strength of the welded joints is critical for the performance of the mesh. Employing advanced welding techniques and quality control measures is essential to produce reliable and durable reinforcing mesh.

3. Customization Each construction project may have specific requirements in terms of mesh size, wire diameter, and spacing. Offering custom solutions can enhance a manufacturer’s value proposition in a competitive market.

4. Compliance with Regulations Manufacturers must stay updated on building codes and regulations to ensure their products fulfill necessary legal and safety standards. This includes understanding the requirements for different regions and project types.

5. Sustainability Practices As the construction industry moves towards sustainability, manufacturers should consider eco-friendly practices. This includes using recycled materials for production, minimizing waste during the manufacturing process, and optimizing transportation to reduce carbon footprints.

6. Market Trends and Innovations Keeping abreast of new technologies in construction and materials science is crucial. Innovations, such as the use of fiber-reinforced polymers or advancements in steel treatments, can enhance the performance of reinforcing mesh.

Conclusion

Reinforcing mesh is an indispensable component for manufacturers involved in the production of concrete slabs. It not only enhances the strength and durability of concrete but also plays a critical role in the overall safety of structures. By focusing on quality materials, advanced manufacturing techniques, and compliance with standards, reinforcing mesh manufacturers can contribute significantly to the future of concrete construction. As the demand for resilient and sustainable construction solutions continues to grow, the role of high-quality reinforcing mesh in concrete slabs remains ever more relevant.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025