Nov . 05, 2024 09:23 Back to list

reinforcing mesh factory

The Importance of Reinforcing Mesh in Construction Insights from a Factory Perspective

Reinforcing mesh, also known as welded wire mesh, plays a pivotal role in the construction industry. As a factory specializing in the production of this material, it is essential to understand its significance, manufacturing process, and the various applications it serves. At its core, reinforcing mesh enhances the structural integrity of concrete, making it a vital component in modern construction.

What is Reinforcing Mesh?

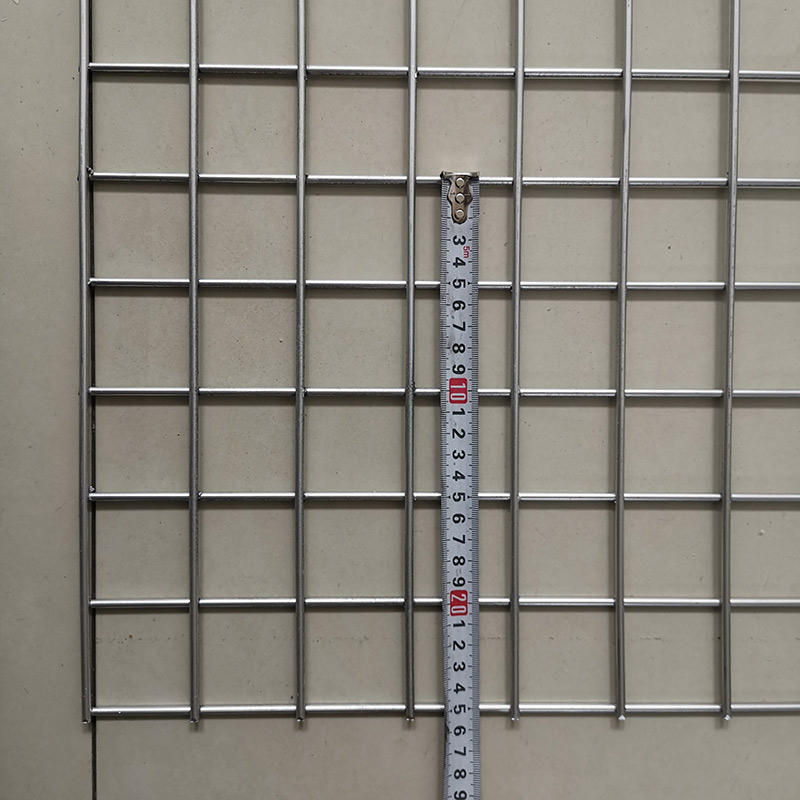

Reinforcing mesh consists of a grid of steel wires that are welded together at intersections. The primary purpose of this material is to provide strength and support to concrete structures. When concrete is poured, the mesh is placed within it to prevent cracking and to manage tensile stresses. This is especially crucial since concrete, while strong in compression, is relatively weak in tension. By incorporating reinforcing mesh, builders can create more durable structures that withstand stress and environmental factors.

The Manufacturing Process

The production of reinforcing mesh involves several key stages, each contributing to the quality and performance of the final product. The process begins with selecting high-quality steel wires, which are then drawn to specific diameters based on industry standards. Once the wires are prepared, they are arranged in a grid formation. Advanced welding techniques are employed to secure the intersections, ensuring that the mesh is both strong and flexible.

After the welding process, the mesh is typically subjected to a rigorous quality control procedure. This ensures that the mesh meets the required specifications, including size, wire diameter, and weld strength. Finally, the finished material is rolled and packaged for distribution. Such manufacturing practices underline the importance of quality assurance in delivering a reliable product to construction businesses.

Applications of Reinforcing Mesh

reinforcing mesh factory

Reinforcing mesh has a wide range of applications across different sectors of construction. In residential buildings, it is commonly used in slab foundations, driveways, and outdoor patios. The mesh reinforces these areas, reducing the risk of cracks and increasing durability over time.

In commercial construction, reinforcing mesh is crucial for the structural integrity of larger buildings. It is used in walls, floors, and roofs to provide the necessary support, especially in high-rise structures where weight distribution is a critical factor. Additionally, its use in precast concrete products, such as wall panels and beams, showcases its versatility and adaptability in various construction scenarios.

The industrial sector also benefits from reinforcing mesh, particularly in the production of storage tanks, silos, and other heavy-duty structures that require robust support systems. The durability of the mesh allows these structures to withstand high pressures and external loads, ensuring safety and longevity.

Environmental Considerations

As the construction industry increasingly focuses on sustainability, reinforcing mesh manufacturers are also seeking ways to reduce their environmental impact. Many factories are adopting eco-friendly practices, such as recycling scrap metal and utilizing energy-efficient machines. This not only lowers the carbon footprint of production but also contributes to a more sustainable construction process.

Conclusion

In summary, reinforcing mesh is a fundamental component in modern construction, providing essential support and enhancing the durability of concrete structures. From its manufacturing process to its wide-ranging applications, reinforcing mesh exemplifies the convergence of engineering and innovation. As the industry continues to evolve, factories dedicated to producing high-quality reinforcing mesh will play an indispensable role in shaping safe, resilient, and sustainable structures for the future. Investing in reinforcing mesh is not just a choice; it is a commitment to quality and longevity in the built environment.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025