Dec . 05, 2024 23:31 Back to list

A Guide to Reinforcing Mesh A393 Production and Quality from Leading Manufacturers

Reinforcing Mesh A393 A Comprehensive Overview of Its Manufacturing and Application

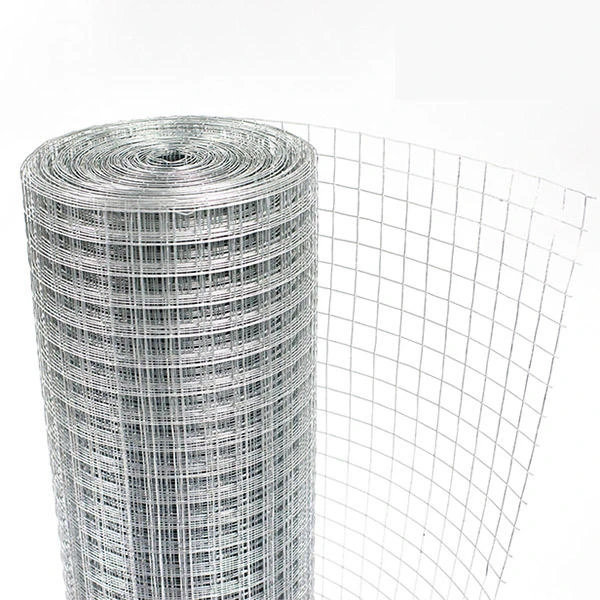

Reinforcing mesh A393 is an essential component in the construction industry, widely utilized for its structural integrity and durability. This article delves into the various aspects of A393 reinforcing mesh, focusing on its manufacturing processes, applications, and the significance of factories that produce this vital construction material.

Understanding A393 Reinforcing Mesh

A393 reinforcing mesh is a type of steel mesh reinforcement used primarily in concrete applications. The designation A393 refers to its specific properties, including dimensions, steel grade, and spacing of the bars that are welded together. Typically, A393 mesh consists of mild steel bars with a diameter of 10 mm and a grid spacing of 200 mm, making it ideal for applications such as flooring, slabs, and other structural components.

The wire used in A393 mesh is usually hot-rolled, providing the necessary strength while maintaining flexibility for ease of installation. Recognized for its high yield strength, A393 mesh is classified under British Standards (BS 4483), ensuring that it meets the stringent requirements set forth for construction materials.

Manufacturing Process of A393 Mesh

The production of A393 reinforcing mesh involves several key processes, typically carried out in specialized factories equipped with advanced machinery. The manufacturing process begins with the selection of high-quality steel wire, which undergoes strict quality control checks to ensure compliance with industry standards.

1. Wire Preparation The steel wire is first processed to the desired diameter and is subjected to treatments to enhance its durability and resistance to corrosion.

2. Welding The prepared wires are then arranged in a grid pattern, where they are meticulously welded at the intersections to form a strong and stable mesh. Automated welding machines are often used to ensure precision and consistency in the welding process, resulting in a uniform product.

3. Quality Control After welding, the mesh undergoes rigorous quality checks. This includes tests for strength, durability, and conformance to the specific dimensions required by the A393 standard.

reinforcing mesh a393 factories

Applications of A393 Reinforcing Mesh

The versatility of A393 reinforcing mesh makes it suitable for a wide array of construction applications. Some of its primary uses include

- Concrete Slabs A393 mesh is commonly used in ground floor slabs, where it helps to prevent cracking and enhances the overall structural integrity. - Suspended Floors The mesh provides critical support in suspended floors, which are essential in multi-storey building constructions.

- Roadways and Pavements In road construction, A393 mesh is used to reinforce asphalt and concrete pavements, contributing to increased load-bearing capabilities and reduced maintenance costs.

- Retaining Walls It is also employed in creating robust retaining walls, helping to secure soil and manage landscaping effectively.

Importance of Factories in A393 Production

Factories that specialize in manufacturing A393 reinforcing mesh play a crucial role in the construction supply chain. These facilities not only ensure a consistent supply of high-quality materials, but they also contribute to advancements in manufacturing technology, leading to improved production efficiency and sustainability.

Moreover, many factories are increasingly adopting eco-friendly practices, focusing on minimizing waste and reducing their carbon footprint. This aligns with the global push for sustainable construction practices, where the environmental impact of construction activities is becoming a significant concern.

Conclusion

Reinforcing mesh A393 is a foundational element in modern construction, ensuring the strength and longevity of various structures. The intricate manufacturing processes carried out in dedicated factories guarantee that this mesh meets the rigorous standards necessary for construction applications. As the demand for reliable and robust construction materials continues to grow, the importance of A393 reinforcing mesh and its manufacturers will remain integral to the industry’s progress and development.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025