Nov . 07, 2024 09:35 Back to list

Reinforcing Mesh A193 Production Insights from Leading Factories in the Industry

Reinforcing Mesh A193 Factories An Overview of Production and Applications

In the construction and engineering industries, reinforcing mesh plays a critical role in enhancing the tensile strength and structural integrity of concrete structures. Among the various types of reinforcing mesh available, A193 mesh is increasingly prominent due to its versatility and robust characteristics. This article delves into the significance of A193 reinforcing mesh factories, exploring their production processes, applications, and the benefits they offer.

Understanding Reinforcing Mesh A193

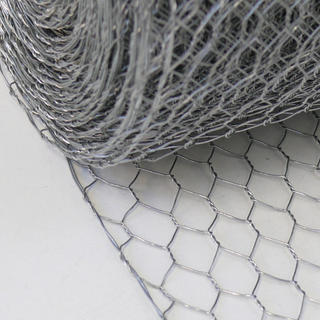

Reinforcing mesh A193 is manufactured from high-quality steel wires. It is characterized by its rectangular or square grid pattern, produced by welding intersections of longitudinal and transverse wires. The designation A193 typically signifies a certain level of strength and ductility, making it suitable for various construction applications. Its properties ensure that it provides exceptional support to concrete, effectively distributing loads and preventing cracks.

The Production Process of A193 Reinforcing Mesh

The manufacturing of reinforcing mesh A193 involves several key steps that ensure the final product meets stringent quality standards. First, raw steel wires are sourced, often treated to enhance their performance. These wires come in varying diameters depending on the required strength and application.

Once the raw materials are ready, the production process begins with cutting the steel wires to the desired lengths. Next, the cut wires are arranged into a grid pattern, where the longitudinal wires run parallel while the transverse wires intersect them at regular intervals. These intersections are either welded together using specialized machines or tied with wires, depending on the factory's capabilities and product specifications.

Quality control is an integral part of the production process. Manufacturers often perform tensile tests and weld quality inspections to ensure consistency and reliability in their products. The finished mesh is then coated with anti-corrosive materials or galvanization to extend its lifespan, making it more durable for use in various environmental conditions.

Applications of Reinforcing Mesh A193

The versatility of A193 reinforcing mesh allows it to be used across numerous construction projects. Common applications include

1. Residential and Commercial Buildings Reinforcing mesh is essential for structural slabs, foundation systems, and walls. It provides the necessary strength to withstand both static and dynamic loads, ensuring long-lasting safety.

reinforcing mesh a193 factories

2. Roads and Pavements A193 mesh is often employed in the construction of roads, bridges, and airport runways. Its ability to distribute loads helps prevent cracking and improves the overall durability of the surface.

3. Civil Infrastructure Projects such as tunnels, dams, and retaining walls benefit significantly from reinforcing mesh, as it enhances stability and supports the structural integrity of these critical facilities.

4. Industrial Applications Factories and warehouses use A193 mesh in heavy concrete floors and walls, where the load-bearing capacity is paramount to operational efficiency.

Benefits of Using A193 Reinforcing Mesh

The use of A193 reinforcing mesh offers several advantages

- Enhanced Load Distribution The primary benefit is its ability to distribute loads evenly across the concrete surface, which helps reduce the risk of cracking and structural failure.

- Cost-Effectiveness Utilizing A193 mesh can be more economical than traditional reinforcement methods, as it requires less material and can be installed quickly.

- Improved Construction Speed Factories are capable of producing large quantities of mesh, allowing for timely delivery to job sites, thus accelerating the construction timeline.

- Customization Many manufacturers offer customization options concerning mesh size, wire diameter, and coating types, catering to specific project requirements.

Conclusion

Reinforcing mesh A193 factories play a vital role in the construction industry, providing essential materials that contribute to the strength and safety of various structures. As construction practices continue to evolve, the demand for high-quality reinforced products such as A193 mesh is expected to rise. By understanding the production processes, applications, and benefits associated with A193 reinforcing mesh, industry professionals can make informed decisions that enhance their projects’ structural integrity and longevity. As we advance, these factories will undoubtedly remain pivotal in shaping the future of modern construction.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025