Nov . 07, 2024 20:50 Back to list

Suppliers of Reinforced Steel Mesh for Construction and Infrastructure Projects

The Importance of Reinforced Steel Mesh in Construction Insights from Suppliers

In the ever-evolving world of construction, the demand for durable and robust materials continues to grow. One such crucial component is reinforced steel mesh, an essential element that enhances the structural integrity of concrete. This article explores the significance of reinforced steel mesh, highlighting insights from suppliers and its applications in various construction projects.

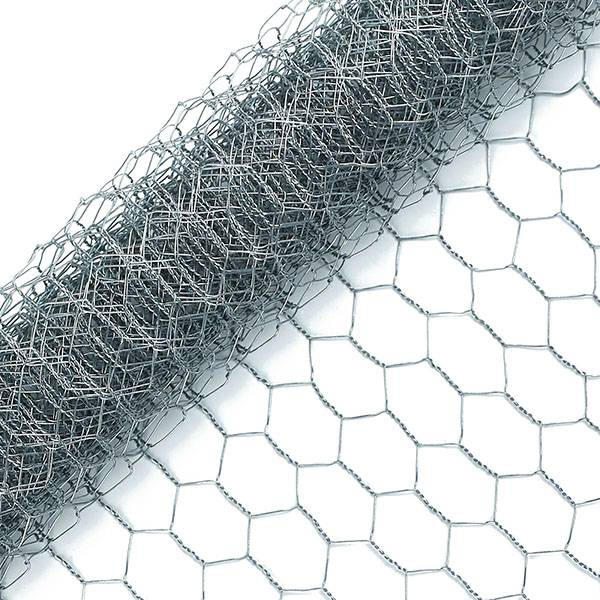

Reinforced steel mesh, often referred to as welded wire mesh, consists of a network of steel wires that are arranged in a grid-like pattern. This mesh is predominantly used in combination with concrete to provide added strength and stability, allowing buildings, bridges, and other structures to withstand various stresses and loads. Suppliers of reinforced steel mesh play a pivotal role in ensuring that construction projects have access to high-quality materials that meet safety and longevity standards.

The Importance of Reinforced Steel Mesh in Construction Insights from Suppliers

Moreover, reinforced steel mesh is versatile and can be utilized in various applications, ranging from residential buildings to large-scale infrastructure projects. For instance, it is commonly used in floor slabs, walls, and foundations. According to suppliers, the increasing trend of using precast concrete elements has further boosted the demand for high-quality reinforced mesh, which is essential for achieving the required strength and durability in these components.

reinforce steel mesh suppliers

Another significant aspect of reinforced steel mesh is its cost-effectiveness. Many suppliers provide various designs and thicknesses to accommodate different budgets without compromising on quality. By using reinforced steel mesh, construction projects can reduce material usage while ensuring structural safety. This economical approach is particularly beneficial in today's construction industry, where managing costs without sacrificing quality is a top priority.

In terms of manufacturing, suppliers of reinforced steel mesh are continuously evolving their production techniques to enhance efficiency and product quality. Advanced technologies, such as automated welding processes, have enabled suppliers to produce mesh with precise dimensions and a higher degree of consistency. Additionally, many suppliers are now focusing on sustainability, sourcing steel from recycled materials and employing eco-friendly practices in their manufacturing processes. This commitment to sustainability not only helps reduce the environmental impact of construction but also meets the growing demand for green building materials.

When selecting a reinforced steel mesh supplier, quality assurance is paramount. Reputable suppliers will often provide certifications and detailed specifications for their products, ensuring that they adhere to relevant building codes and standards. Furthermore, they should offer expert advice on the most suitable mesh type for specific applications, helping contractors and builders make informed decisions.

In conclusion, reinforced steel mesh is a vital component in modern construction, offering strength, versatility, and cost savings. As the industry continues to evolve, suppliers are increasingly focused on quality, innovation, and sustainability, ensuring that clients receive reliable materials tailored to their needs. By partnering with reputable reinforced steel mesh suppliers, construction professionals can enhance the structural integrity of their projects, paving the way for safe and durable buildings that stand the test of time.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025