Dec . 13, 2024 01:52 Back to list

Quality Reinforcement Weld Wire Mesh Suppliers for Construction and Industrial Applications

The Importance of Reinforcement Weld Wire Mesh A Comprehensive Overview

Reinforcement weld wire mesh is an essential component in the construction industry, known for its robust applications in providing structural integrity to various projects. Manufacturers of this material play a pivotal role in ensuring that construction sites are equipped with high-quality solutions that can withstand the test of time. This article aims to explore the significance of reinforcement weld wire mesh, its manufacturing process, and the advantages it offers.

What is Reinforcement Weld Wire Mesh?

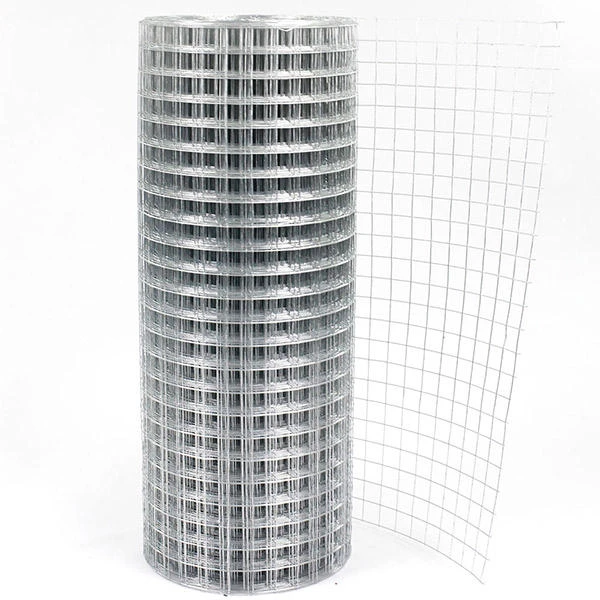

Reinforcement weld wire mesh consists of longitudinal and transverse wires that are welded together at their intersections. This creates a strong grid-like structure that enhances the tensile strength of concrete. Commonly used in floors, roofs, walls, and pavements, this mesh provides a uniform distribution of stress throughout the concrete, thus preventing cracking and other structural failures.

Manufacturing Process

The production of reinforcement weld wire mesh involves several steps that ensure its durability and effectiveness. Initially, high-quality steel wires are drawn to specific gauge sizes. The wires are then arranged in a grid configuration, with precise spacing determined by the project requirements. Once the wires are set, they undergo a welding process, where they are electrically fused at their intersections. This welding method ensures a consistent and strong bond, resulting in a mesh that can comfortably support heavy loads.

After welding, the mesh is typically subjected to various treatments, such as galvanization, which involves coating the steel with a layer of zinc. This zinc coating helps in protecting the mesh from corrosion, extending its lifespan and maintaining its structural integrity over time.

Advantages of Reinforcement Weld Wire Mesh

1. Increased Load-Bearing Capacity The primary advantage of using reinforcement weld wire mesh is its ability to significantly enhance the load-bearing capacity of concrete structures. By redistributing stress, it prevents localized failures and promotes longevity.

reinforcement weld wire mesh manufacturer

2. Ease of Installation Weld wire mesh is relatively easy to handle and install. It comes in standard sheets or rolls, making it convenient for construction workers to deploy on sites. This can lead to time and labor cost savings during the installation process.

3. Reduced Crack Formation The integration of weld wire mesh in concrete can help minimize the occurrence of cracks that typically arise due to thermal expansion, contraction, or settling. This characteristic is particularly beneficial for large surface areas like driveways and parking lots.

4. Cost-Effectiveness Compared to other reinforcement methods, such as the use of rebar, weld wire mesh can often be a more cost-effective solution for projects that require significant structural support without compromising quality.

5. Versatility Weld wire mesh is suitable for a variety of applications, including residential, commercial, and industrial construction. Its compatibility with various types of concrete makes it a versatile choice for different project requirements.

Applications

The applications for reinforcement weld wire mesh are vast and diverse. It is commonly found in foundations, slabs, precast concrete elements, and even in road construction, providing critical support in concrete pavements and bridges. Additionally, its use in retaining walls and fencing highlights its multifunctionality within the construction sector.

Conclusion

In conclusion, reinforcement weld wire mesh is an indispensable material in modern construction, providing enhanced structural integrity and durability to concrete structures. Manufacturers dedicated to producing high-quality weld wire mesh contribute significantly to the safety and longevity of buildings and infrastructure. As sustainability and efficiency become increasingly paramount in construction practices, the importance of reliable materials such as reinforcement weld wire mesh cannot be overstated. Investing in quality mesh solutions is crucial for any construction project, ensuring both the safety and effectiveness of the structures built.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025