Nov . 12, 2024 18:00 Back to list

reinforcement weld wire mesh manufacturer

Reinforcement Weld Wire Mesh A Comprehensive Overview of Manufacturing and Applications

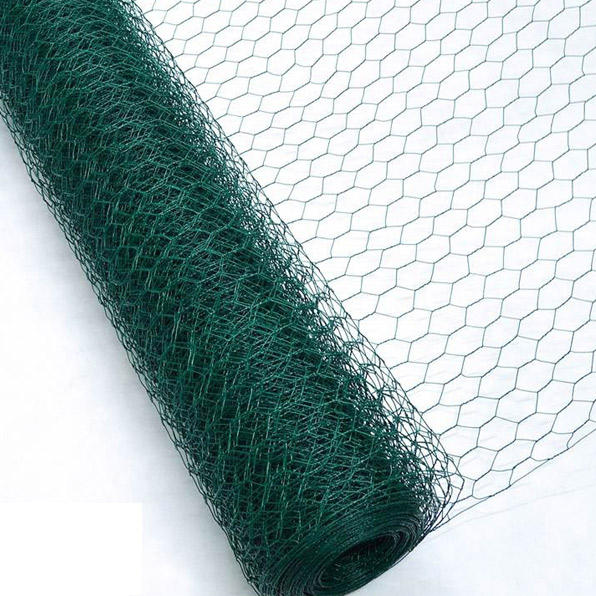

Reinforcement weld wire mesh, commonly referred to as welded wire mesh, is a crucial component in the construction industry, providing robust structural support to a variety of building projects. This article offers an in-depth look at the manufacturing process, applications, and benefits of reinforcement weld wire mesh, highlighting why it has become a staple for builders and architects worldwide.

Manufacturing Process

The production of reinforcement weld wire mesh involves weaving together strips of wire to create a consistent grid pattern. The manufacturing process typically follows these steps

1. Wire Selection The first step involves selecting the appropriate type of wire, which can be made from various materials such as stainless steel, carbon steel, or galvanized steel. Each material is chosen based on the intended application and environmental exposure.

2. Wire Drawing The chosen wire is then drawn to the desired thickness. This is a crucial step that determines the strength and flexibility of the mesh. Thinner wires create a more flexible mesh, while thicker wires provide greater strength.

3. Mesh Fabrication After drawing, the wires are arranged in a grid format, with the horizontal wires laid parallel to each other, and vertical wires inserted at regular intervals. The spacing between the wires can vary depending on the mesh's intended use.

4. Welding Process Once the wires are properly aligned, they undergo a welding process where the intersections of the wires are fused together using electric resistance welding. This creates a strong and stable mesh that can withstand significant loads.

5. Finishing Touches After welding, the mesh is often treated with protective coatings, like galvanization, to enhance its resistance to corrosion and rust. This treatment is particularly important for applications in harsh environments.

Applications of Reinforcement Weld Wire Mesh

Reinforcement weld wire mesh is utilized in a wide range of applications due to its versatility and strength. Some of the primary applications include

1. Concrete Reinforcement One of the most common uses for welded wire mesh is in concrete reinforcement. It is embedded within concrete slabs, walls, and columns to enhance the structural integrity and prevent cracking.

reinforcement weld wire mesh manufacturer

2. Road and Bridge Construction In civil engineering projects, welded wire mesh is used to reinforce asphalt pavement, roadways, and bridges. Its ability to distribute loads evenly helps to prolong the lifespan of these structures.

3. Agricultural Fencing Farmers often utilize welded wire mesh for fencing purposes. It provides a durable barrier to protect livestock and crops from predators and harsh weather conditions.

4. Architectural and Decorative Features Beyond its structural applications, reinforcement weld wire mesh is often employed in decorative elements of building design, such as facades, railings, and partitions, adding an aesthetic value while maintaining functionality.

Benefits of Using Reinforcement Weld Wire Mesh

The advantages of using reinforcement weld wire mesh in construction and other industries are numerous

1. Strength and Durability Welded wire mesh offers superior strength compared to traditional reinforcement methods, capable of bearing substantial loads and stresses.

2. Cost-Effectiveness Its manufacturing process allows for the creation of large sheets, reducing labor costs and material waste. This translates into economic benefits for builders and contractors.

3. Ease of Installation Welded wire mesh is relatively lightweight and easy to handle, making it straightforward to transport and install on construction sites.

4. Versatile Design Options The customizable nature of welded wire mesh allows it to be fabricated in various dimensions and configurations, accommodating the specific needs of any project.

5. Environmental Resistance With the right materials and coatings, welded wire mesh exhibits excellent resistance to environmental factors such as moisture, chemicals, and extreme temperatures.

Conclusion

In summary, reinforcement weld wire mesh is an indispensable element in modern construction, combining strength, versatility, and cost-effectiveness. As the construction industry continues to evolve, the demand for high-quality welded wire mesh is likely to grow. Understanding the manufacturing process and recognizing the myriad applications and benefits can help builders make informed decisions that enhance the safety and durability of their projects. Whether for roads, bridges, buildings, or agricultural fencing, reinforcement weld wire mesh stands out as a reliable solution for structural reinforcement.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025