Nov . 10, 2024 17:30 Back to list

12mm Reinforcement Steel Bars Quality Manufacturers for Construction Projects

Choosing the Right Manufacturer for 12mm Reinforcement Steel Bars

When it comes to construction, the importance of quality materials cannot be understated. One such critical component is reinforcement steel bars, commonly known as rebar, which provide tensile strength to structures. Among the various sizes available, the 12mm reinforcement steel bar is widely used due to its suitable balance of strength and flexibility. In this article, we will discuss what to look for when choosing a manufacturer for 12mm reinforcement steel bars and the inherent benefits of selecting a reputable provider.

Understanding Reinforcement Steel Bars

Reinforcement steel bars are typically made from carbon steel and are designed to be incorporated into concrete to ensure durability and structural integrity. The primary purpose of using rebar is to enhance the tensile strength of concrete, which is naturally strong in compression but weak in tension. The 12mm rebar is favored in many construction projects, including residential buildings, bridges, and industrial structures, due to its versatility and adequate load-bearing capacity.

Key Factors to Consider When Choosing a Manufacturer

1. Quality Assurance and Standards Quality is paramount when it comes to reinforcement steel bars. Reputable manufacturers adhere to national and international standards such as ASTM, BS, or ISO certifications. Ensure that the manufacturer provides documentation supporting their compliance with these standards, which guarantees that the bars meet specific performance criteria.

2. Material Transparency It is essential to know the composition of the steel used in manufacturing rebar. High-quality steel should contain an optimal mix of elements to ensure strength, durability, and resistance to corrosion. Manufacturers should be transparent about the materials sourced for production and should ideally provide material test reports.

3. Production Process Understanding the production techniques employed by the manufacturer can give you insight into the quality of the final product. Look for companies that utilize advanced technology and processes such as hot rolling or cold working. The use of modern machinery often results in better consistency and quality in the finished rebar.

reinforcement steel bar 12mm manufacturer

4. Customizations and Sizes A reliable manufacturer should be capable of providing a range of products, not just the standard sizes like 12mm rebar. The ability to customize dimensions, grades, and coatings can be beneficial for specialized projects. Check if the manufacturer offers additional services like cutting and bending, which can save time and costs on the job site.

5. Delivery and Logistics Efficient logistics and timely delivery can significantly impact the workflow of a construction project. Choose a manufacturer with a proven track record of meeting delivery deadlines. Good manufacturers often have a well-planned supply chain and can provide a seamless delivery process.

6. Customer Service and Support Excellent customer service can make a considerable difference in your experience with a manufacturer. Assess the support offered, including pre-sale consultations and after-sale services. A responsive and knowledgeable team can assist you in making informed decisions and resolving any issues that arise.

7. Reputation and Reviews One of the most effective ways to gauge the reliability of a manufacturer is through customer reviews and testimonials. Research online, ask for references, and consider the reputation of the manufacturer in the industry. A company with a strong positive reputation is more likely to deliver quality products.

Benefits of Choosing a Reputable Manufacturer

Choosing the right manufacturer for your 12mm reinforcement steel bars can lead to numerous advantages, including

- Enhanced Structural Integrity Quality rebar ensures that your structures withstand the test of time and environmental conditions. - Cost-Effectiveness While it may be tempting to opt for cheaper alternatives, investing in quality rebar can save costs in the long run by reducing the need for repairs and replacements. - Safety Assurance Using high-quality products minimizes the risks of structural failure, ensuring the safety of the building and its occupants.

In conclusion, selecting the right manufacturer for 12mm reinforcement steel bars is a critical decision that can profoundly influence the success and durability of your construction projects. By considering factors such as quality assurance, material transparency, and customer support, you can make an informed choice that aligns with your project requirements and budget. Always prioritize quality and reliability, as the safety and longevity of the structures you build depend on it.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

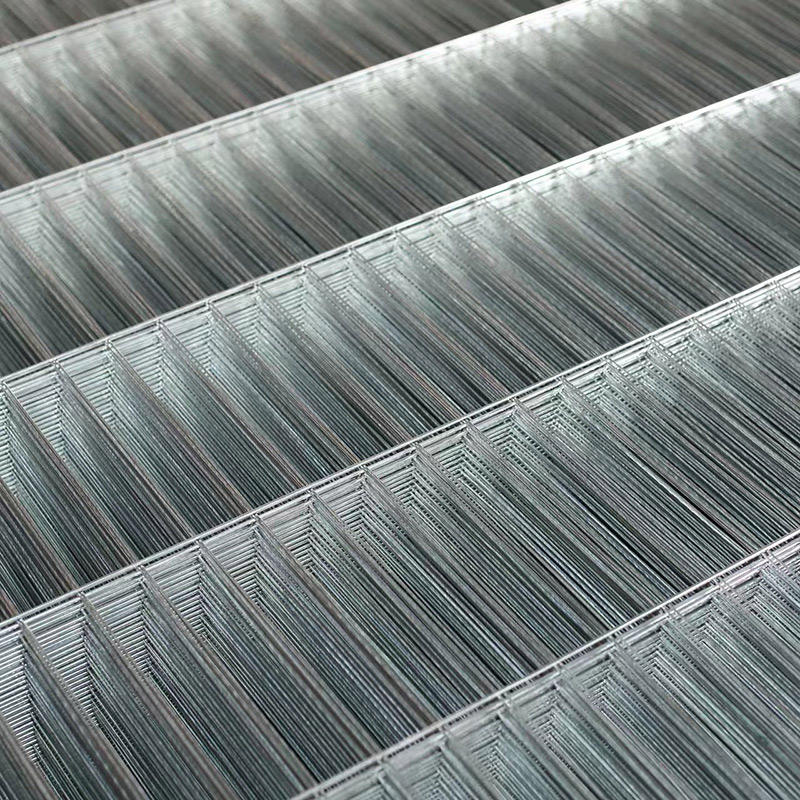

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025