Nov . 09, 2024 02:14 Back to list

12mm Reinforcement Steel Bar Manufacturers and Suppliers for Construction Industry

The Essentials of 12mm Reinforcement Steel Bars Insights into Manufacturing

Reinforcement steel bars, commonly known as rebar, are pivotal components in the construction industry, providing the necessary tensile strength to concrete structures. Among the various sizes available, 12mm reinforcement steel bars are particularly notable for their versatility and widespread use in a range of applications, including residential buildings, bridges, roads, and other infrastructures. In this article, we will explore the manufacturing processes, significance, and quality considerations of 12mm reinforcement steel bars, shedding light on the factories that produce them.

Manufacturing Processes

The production of 12mm reinforcement steel bars begins with high-quality raw materials, usually in the form of scrap metal or direct reduced iron (DRI). Factories utilize advanced technologies such as Electric Arc Furnaces (EAF) or Basic Oxygen Furnaces (BOF) to melt the raw materials. This primary stage of manufacturing is crucial, as the quality of the steel at this point will influence the overall performance of the final product.

Once the molten steel is produced, it undergoes a process called continuous casting, which involves pouring the molten steel into molds to create semi-finished products like billets. These billets are then heated and rolled through a series of mills at high temperatures, transforming them into the desired diameter of 12mm. The rolling process not only shapes the bars but also aligns the internal microstructure of the steel, enhancing its physical properties.

After the rolling is complete, the bars are cooled, often through a quenching process that allows for greater strength and durability. The final stage includes cutting the bars into specified lengths, usually 12 meters, and performing inspections and tests to ensure they meet the relevant industry standards.

Significance of 12mm Reinforcement Steel Bars

The significance of 12mm reinforcement steel bars lies in their strength, versatility, and ease of use. Being neither too thick nor too thin, they are ideal for a range of applications, from residential projects to more demanding infrastructure endeavors. In constructing buildings, 12mm rebar is widely utilized in slab reinforcement, columns, and foundations, providing essential support that helps withstand tensile forces.

reinforcement steel bar 12mm factories

Moreover, the relatively lighter weight of 12mm bars compared to larger sizes allows for easier handling and installation, which can lead to reduced labor costs and shorter project timelines. Additionally, because they are used in numerous applications worldwide, 12mm rebar has become a standardized size, making it easily available and cost-effective.

Quality Considerations

Quality control is paramount in the manufacturing of 12mm reinforcement steel bars. Reputable factories adhere to established standards such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) to ensure their products are durable, strong, and reliable. Quality testing typically involves checking tensile strength, yield strength, and elongation properties of the rebar.

Factories often invest in modern testing equipment and techniques to rigorously assess the quality of their output. These tests help identify any inconsistencies or defects in the steel. Furthermore, manufacturers may also conduct third-party audits and certifications to bolster their credibility and assure customers of the quality of their products.

Another essential consideration is the coating of rebar to enhance its resistance to corrosion, especially in environments exposed to extreme weather conditions or chemical attacks. Factors such as galvanization or epoxy coating can prolong the lifespan of 12mm reinforcement steel bars, making them a more sustainable choice in construction.

Conclusion

The manufacturing of 12mm reinforcement steel bars is a complex process requiring precision, quality control, and adherence to industry standards. As a critical material in the construction sector, these bars contribute significantly to the safety and durability of structures. With the ongoing advancements in manufacturing technologies and the emphasis on sustainability, the future of 12mm rebar production remains promising, catering to the evolving demands of modern construction practices. Whether engaged in building homes or infrastructure, understanding the importance and intricacies of rebar can aid stakeholders in making informed decisions about materials that will form the backbone of their projects.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

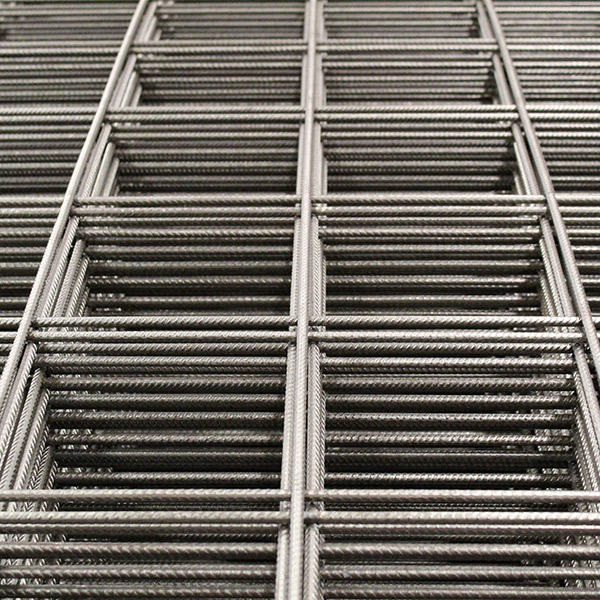

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025