Oct . 07, 2024 17:00 Back to list

reinforcement mesh manufacturers

Understanding Reinforcement Mesh Manufacturers A Key Player in Construction

In the world of construction, the integrity and longevity of structures are paramount. One crucial component that contributes significantly to this aspect is reinforcement mesh. Reinforcement mesh, also known as welded wire mesh, is an essential material used in reinforcing concrete, helping to improve its tensile strength and durability. This article delves into the role of reinforcement mesh manufacturers, their products, and the importance of choosing the right supplier for construction projects.

What is Reinforcement Mesh?

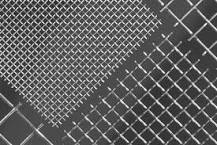

Reinforcement mesh is a grid-like structure made from steel wires that are welded together at their intersections. This product is utilized in various construction projects, including slabs, pavements, walls, and foundations. The mesh is designed to bear tensile and shear forces, which helps prevent cracking and structural failures in the concrete. By distributing loads and enhancing the overall resilience of concrete structures, reinforcement mesh plays a crucial role in improving safety and performance.

The Role of Manufacturers

Reinforcement mesh manufacturers are pivotal in the construction supply chain. They are responsible for producing high-quality mesh products that meet industry standards and specific project requirements. The manufacturing process often involves drawing steel into wires, which are then cut, shaped, and welded to form the mesh sheets. This process must be precise and adhere to strict quality control measures to ensure the final product's effectiveness.

Moreover, manufacturers offer various types of reinforcement mesh, including different wire diameters, spacing, and configurations. These variations help cater to the diverse needs of construction projects, ranging from residential buildings to large-scale infrastructure works. Additionally, some manufacturers provide custom solutions, allowing engineers and architects to specify the exact dimensions and characteristics required for their projects.

Quality and Standards

One of the critical aspects of working with reinforcement mesh is ensuring that the products comply with local and international standards. Quality assurance is vital in the construction industry, as subpar materials can lead to significant safety risks and financial losses. Reputable manufacturers adhere to established guidelines, such as ASTM (American Society for Testing and Materials) or EN (European Norm), ensuring that their products meet specific performance criteria.

When selecting a reinforcement mesh manufacturer, potential clients should inquire about the certifications and testing processes employed by the supplier

. This transparency is crucial in gaining confidence that the materials used will hold up under the rigors of construction and meet all necessary safety standards.reinforcement mesh manufacturers

Advantages of Sourcing from Established Manufacturers

Choosing an established reinforcement mesh manufacturer comes with various advantages

1. Quality Assurance Reputable suppliers often have stringent quality control measures and earned a solid reputation for providing reliable products.

2. Technical Expertise Established manufacturers usually have experienced staff who can offer valuable insights and support during the selection process, helping clients choose the right type of mesh for their specific needs.

3. Innovation Many reputable manufacturers invest in research and development to create improved mesh products, advanced manufacturing techniques, and new materials that enhance construction practices.

4. Timely Delivery Larger manufacturers with efficient logistics can ensure that materials are delivered on time, which is crucial for the timely progression of construction projects.

5. After-Sales Support A reliable manufacturer often provides after-sales support, including guidance on installation, handling, and troubleshooting.

Conclusion

Reinforcement mesh manufacturers play a pivotal role in the construction industry by providing essential materials that enhance the safety and durability of concrete structures. With numerous options available, it is crucial for construction professionals to partner with reputable manufacturers that prioritize quality, adhere to industry standards, and offer technical expertise. By doing so, they ensure that their projects are built on a foundation of reliability, ultimately leading to the successful completion of safer and more resilient structures. As construction technology evolves, the role of these manufacturers will continue to be integral to the industry’s advancement and stability.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025