Dec . 03, 2024 16:50 Back to list

reinforced welded mesh manufacturer

The Importance of Reinforced Welded Mesh in Construction

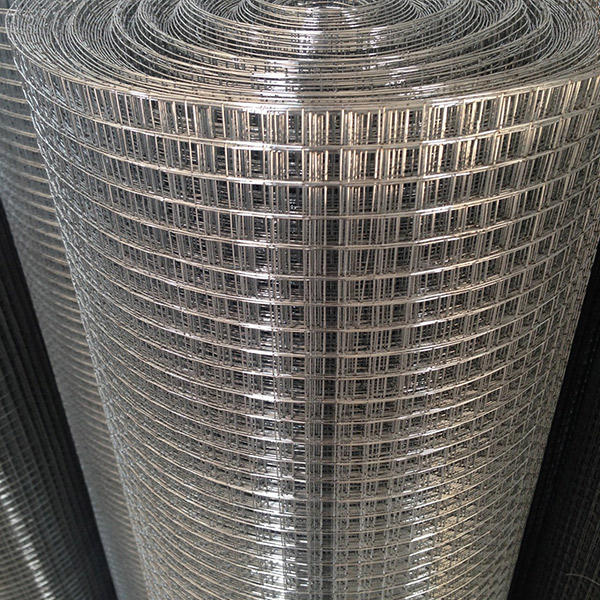

Reinforced welded mesh has become an essential component in various construction applications, providing sturdiness, reliability, and unparalleled support. As a key material utilized in concrete reinforcement, this product ensures the durability and longevity of structures, making it a staple for manufacturers and builders alike.

What is Reinforced Welded Mesh?

Reinforced welded mesh consists of intersecting wires—typically made of steel—that are welded at various points to create a grid-like structure. This mesh can be produced in a range of sizes and diameters, depending on the specific requirements of the project. The welding process not only strengthens the individual wires but also ensures that the mesh maintains its shape under pressure.

Applications of Reinforced Welded Mesh

Reinforced welded mesh is versatile and is used in diverse applications across the construction industry. It is primarily employed in

1. Concrete Slabs The mesh is placed within concrete slabs during construction. Its presence helps distribute loads evenly and minimizes the chances of cracking, which can significantly enhance the lifespan of the structure.

2. Walls and Foundations In walls and foundations, reinforced welded mesh provides additional support, particularly in areas that may experience shifting or settling. This reinforcement is crucial for maintaining structural integrity.

3. Roads and Highways In road construction, welded mesh can be used in the design of pavements and bridge decks. It helps to resist shear forces and contributes to the overall stability of the roadway.

4. Precast Concrete Products Manufacturers of precast concrete products, such as beams, columns, and panels, rely heavily on reinforced welded mesh to achieve the required strength and durability during production.

Benefits of Using Reinforced Welded Mesh

reinforced welded mesh manufacturer

The advantages of using reinforced welded mesh in construction are numerous

- Cost-Effectiveness Compared to traditional rebar, welded mesh is often more cost-effective, reducing material and labor costs during installation. The quick assembly allows for faster project completion.

- Uniform Strength Distribution The uniformity of the welded mesh ensures that stress is evenly distributed across the structure, minimizing points of weakness.

- Ease of Handling Welded mesh is lighter and easier to handle than solid rebar, making transportation and installation simpler and more efficient.

- Sustainability Many manufacturers focus on sustainable practices when producing reinforced welded mesh. The materials used can often be recycled, contributing to environmentally friendly construction practices.

Choosing the Right Manufacturer

Selecting a reliable reinforced welded mesh manufacturer is crucial for ensuring the quality and performance of the product. A reputable manufacturer will adhere to industry standards, utilize high-grade materials, and provide thorough testing to ensure the mesh meets necessary specifications.

It's also essential to consider factors such as customer service, delivery times, and customization options. A manufacturer that understands the unique needs of each project can help tailor products to ensure optimal results.

Conclusion

In summary, reinforced welded mesh is an indispensable material in modern construction. Its strength, versatility, and cost-effectiveness make it ideal for a wide range of applications, from residential buildings to large infrastructure projects. As the demand for durable and reliable construction materials continues to grow, the importance of high-quality reinforced welded mesh will only increase. Choosing the right manufacturer is key to achieving the best results, ensuring that projects are completed on time and within budget while meeting all safety and quality standards.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025