Oct . 17, 2024 17:29 Back to list

Suppliers of Custom Designed G.I. Wire for Various Applications

Understanding Redrawn G.I. Wire Suppliers A Comprehensive Overview

Redrawn galvanized iron (G.I.) wire plays a crucial role in various industries due to its strength, durability, and resistance to corrosion. As a fundamental material, G.I. wire is used in construction, agriculture, fencing, and many other applications. In this article, we will delve into the significance of redrawn G.I. wire, explore the suppliers in the market, and highlight key factors to consider when choosing the right supplier.

What is Redrawn G.I. Wire?

Redrawn G.I. wire is produced through a process where galvanized wire is drawn through a die to reduce its diameter while increasing its tensile strength. The galvanization process involves coating the iron wire with a layer of zinc, which offers protection against rust and corrosion. This makes redrawn G.I. wire particularly suitable for outdoor applications where exposure to the elements is a concern. The reduction in diameter not only enhances the wire's strength but also improves its flexibility, making it easier to work with in various applications.

Applications of Redrawn G.I. Wire

Redrawn G.I. wire is widely used across numerous sectors

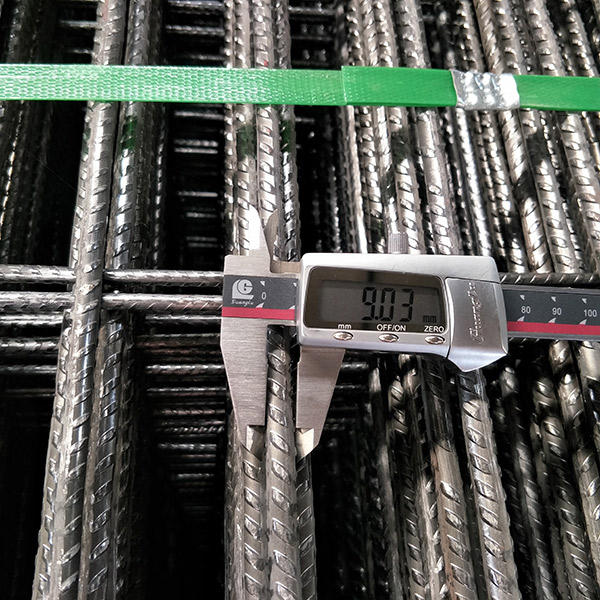

1. Construction In construction projects, redrawn G.I. wire serves as a crucial reinforcement material for concrete structures, offering added tensile strength and helping to prevent cracking.

2. Agriculture Farmers utilize G.I. wire for fencing, trellising crops, and supporting structures for fruit-laden plants. Its durability ensures long-lasting solutions in the agricultural sector.

3. Manufacturing In manufacturing settings, redrawn G.I. wire is used in the production of meshes, nets, and other wire products that require a high tensile strength and corrosion resistance.

4. Craft and Art Artists and crafters often use G.I. wire due to its malleability and strength, making it an ideal choice for sculptures, jewelry, and other creative projects.

redrawn g.i. wire suppliers

Selecting the Right Supplier

When seeking redrawn G.I. wire suppliers, it is imperative to consider several key factors to ensure you choose a reliable and quality provider

1. Quality Assurance The quality of G.I. wire can vary significantly among suppliers. It is essential to select a supplier that adheres to international standards and provides detailed specifications about their products, such as tensile strength, diameter variations, and zinc coating thickness.

2. Experience and Reputation Suppliers with a proven track record and positive customer feedback are generally more trustworthy. Researching a supplier's history, industry experience, and reputation can help you make an informed decision.

3. Range of Products A good supplier should offer a variety of wire sizes, types, and grades. This ensures that you can find the right material for your specific needs without having to look elsewhere.

4. Customer Service Exceptional customer service is a hallmark of a quality supplier. Ensure that the supplier is responsive to inquiries, provides clear information, and is willing to assist with your needs.

5. Pricing and Terms Compare prices among different suppliers, but remember that the lowest price may not always equate to the best quality. Also, consider the payment terms, delivery schedules, and return policies when making your choice.

Conclusion

Redrawn G.I. wire is an essential material in various industries due to its strength and resistance to corrosion. Choosing the right supplier is crucial for obtaining quality wire that meets your specific application needs. By carefully considering factors such as quality assurance, experience, product range, customer service, and pricing, you can ensure a successful partnership with a reliable redrawn G.I. wire supplier. Whether you need it for construction, agriculture, manufacturing, or creative projects, the right wire can make all the difference in the success of your endeavors.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025