Dec . 10, 2024 16:16 Back to list

redrawn g.i. wire factory

The Redrawn G.I. Wire Factory A New Era in Manufacturing

In the heart of industrial innovation, the Redrawn G.I. Wire Factory stands as a beacon of modern manufacturing techniques and sustainability. This facility has transformed the way galvanized iron (G.I.) wire is produced, emphasizing efficiency and environmental responsibility. As industries worldwide pivot toward more sustainable practices, the Redrawn G.I. Wire Factory embodies this shift, showcasing cutting-edge technology alongside a commitment to minimizing ecological impact.

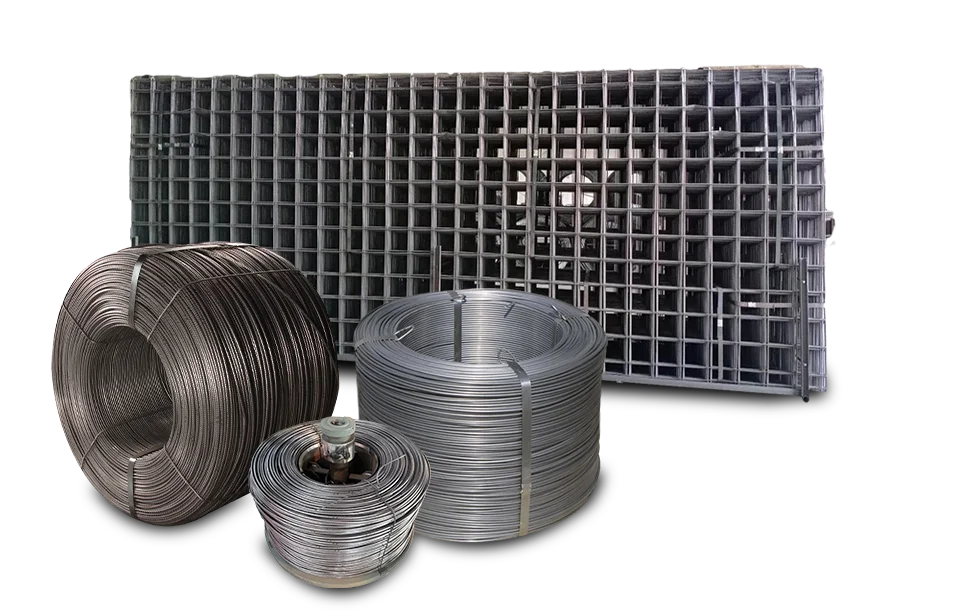

The factory specializes in creating high-quality galvanized iron wire, essential for various applications, including construction, fencing, and crafting. The process begins with the careful selection of raw materials, ensuring that only the highest-grade steel is used. This steel is then drawn down into wire of varying thicknesses, a meticulous process that enhances the wire's tensile strength and durability.

The Redrawn G

.I. Wire Factory A New Era in ManufacturingThe galvanization process that follows the drawing of the wire is equally innovative. Traditionally, galvanization involved the use of harsh chemicals and methods that could harm the environment. At the Redrawn G.I. Wire Factory, a state-of-the-art hot-dip galvanizing technique is employed. This method not only effectively coats the wire in zinc—providing corrosion resistance and extending the wire's lifespan—but also utilizes eco-friendly materials and less energy than conventional methods. Moreover, this process features advanced filtration systems that clean any runoff, ensuring that no toxic substances are released into the surrounding ecosystem.

redrawn g.i. wire factory

Employee safety and welfare are particularly prioritized at the Redrawn G.I. Wire Factory. The factory implements strict safety protocols and provides comprehensive training to ensure that all workers are equipped to handle equipment and materials safely. An emphasis on ergonomics in the workplace design reduces the risk of injury and enhances productivity. This holistic approach to worker welfare creates a positive working environment, which can lead to greater job satisfaction and retention rates—a crucial aspect in the competitive manufacturing industry.

Furthermore, the factory recognizes the importance of community engagement. By establishing partnerships with local schools and vocational programs, the Redrawn G.I. Wire Factory contributes to workforce development. In addition to providing job opportunities, the factory offers internships and apprenticeships for students interested in manufacturing careers. This commitment to education and local economic development helps to cultivate a skilled workforce, ensuring the factory and the industry as a whole can continue to thrive.

The Redrawn G.I. Wire Factory is not merely a manufacturing facility; it is a symbol of what the future of industry can look like—where efficiency, sustainability, and community engagement coexist. As it continues to innovate and adapt to new challenges, the factory serves as a model for similar enterprises aiming to balance economic goals with ecological responsibility.

In conclusion, the Redrawn G.I. Wire Factory exemplifies the transformative potential of modern manufacturing. By leveraging technology, prioritizing sustainability, and committing to the well-being of its employees and community, the factory is setting new standards in the industry. It is paving the way for a future where the production of essential materials does not come at the expense of the planet, but rather seeks to protect and preserve it for generations to come.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025